THE BREW DAY

Stand by this is a monster with over 30 pictures and has taken me 1.5 hours to write up & post, so comment whatever you think to make it worth it

Having spent the previous day setting it up and knowing that afterwards I would be driving for over 5 hours I got up a little earlier than usual to make the coffee check on the yeast and set the HLT up to get to strike water temps.

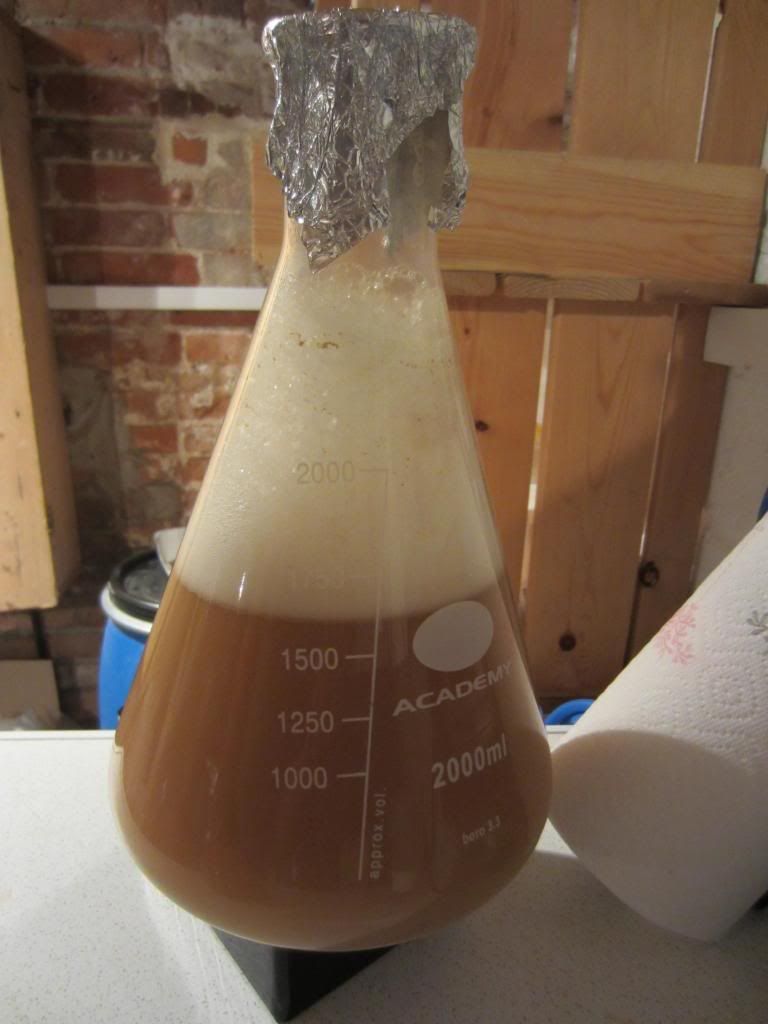

This is after 3 days, note that the stir bar is still in the flask at this point, don't forget and pitch the whole lot or you will be waiting until after fermentation is over before you can safely retrieve it. Or of course if you forget pour the trub down the drain along with the stir bar.

Doughing in: First problem of the day the strike water was too hot so I left it whilst I went back upstairs for something and by the time I got back it was too low, tried to rescue with some boiled water but couldn't get it high enough without seriously diluting the mash and of course petentially ruining the mash pH, more of that later.

I made this insulation hood for my Igloo cool box, very simple, it has to be for me, and rarely loses more than 1/2 a degree over 1 hour, this actually went for a full 90 minutes.

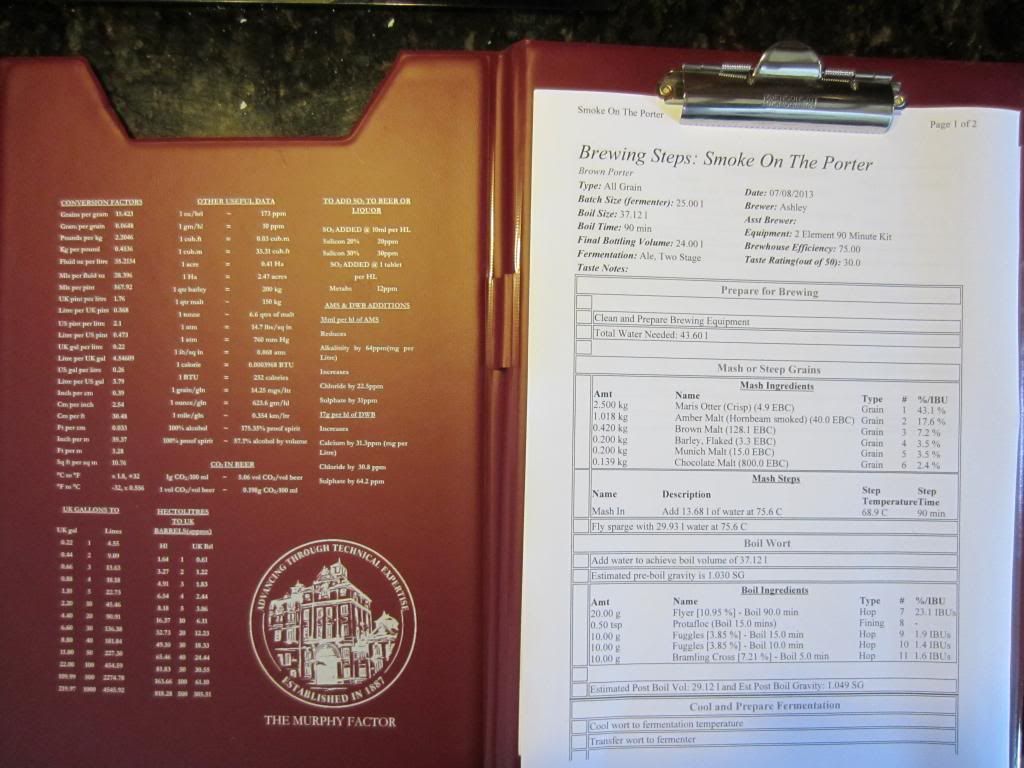

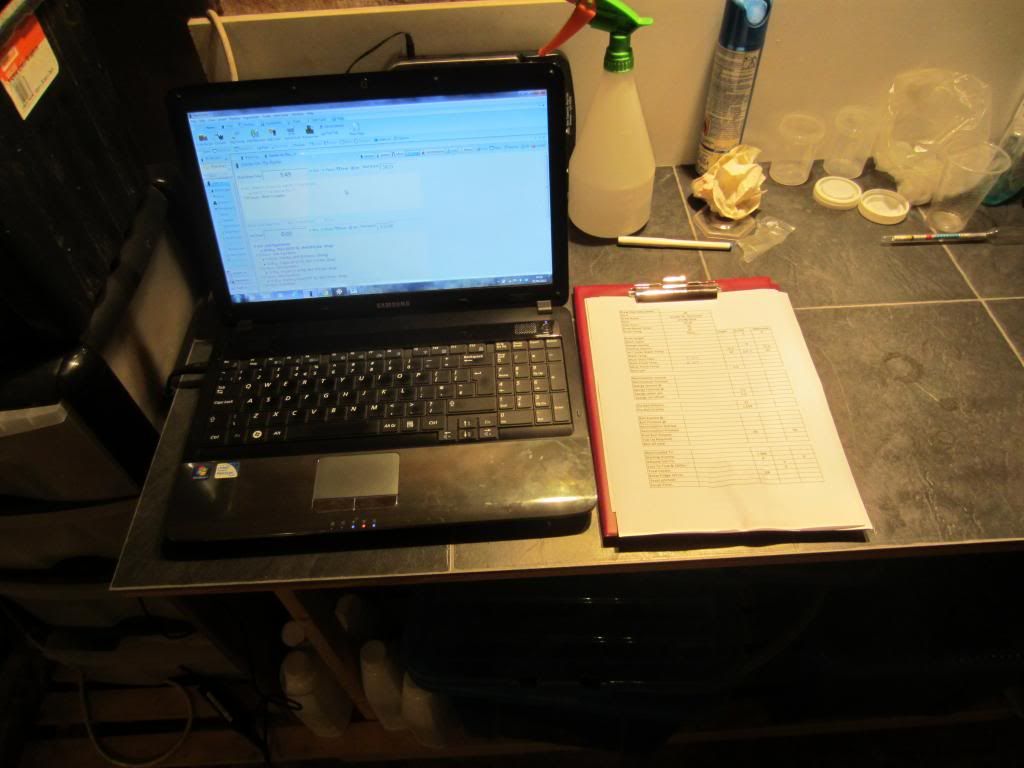

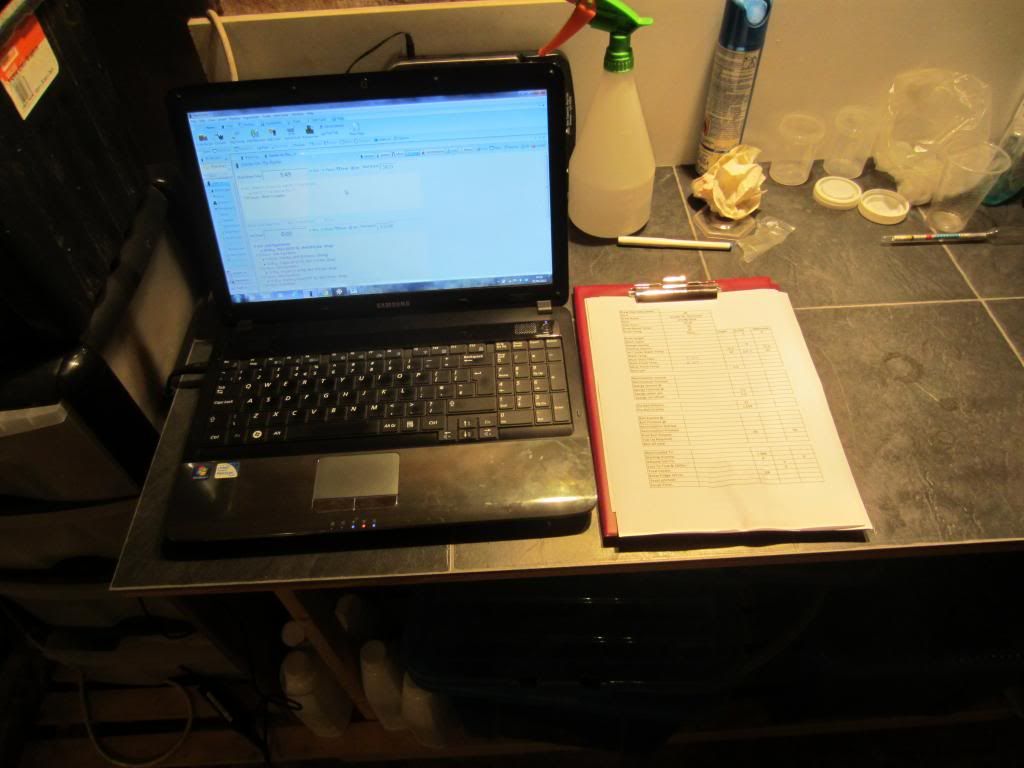

This shot shows me running Beersmith software and using a brew day data capture sheet I created in Excel. It is designed to be an aide memoire for when I write up the notes for putting into Beersmith and then keeping with my printouts of the Beersmith recipe, water treatment sheet and the brew day data sheet. They are put into a plastic document sleeve and kept in a ring binder. I don't trust software

Whilst the mash is doing its thing I pump the sparge water up to the HLT form the boiler, I usually start heating the sparge water in the boiler before pumping up to give it a start, just remember to turn the elements off before you pump below them

. You can see the little solar pump chugging away, takes about 30 minutes at this height, also note the black lead going from the STC 1000 to the HLT, this is the sensor which will monitor the temp of the HLT during the sparge, now a lot of guys will say that is nowhere near good enough as there will be all sorts of differing temps throughout the liquour in there, but it is a reasonably inexpensive way of doing this and maximises the use of the STC. Just make sure the relay on the hot side is rated correctly, I believe mine is 40 amp (came from Cedaronics).

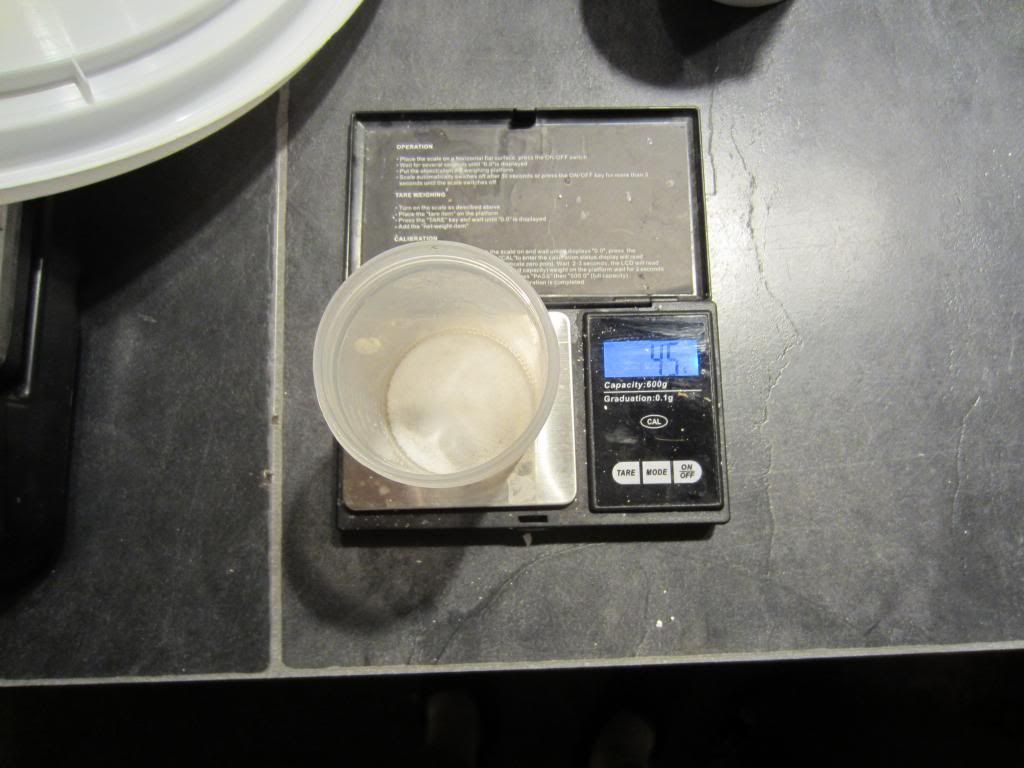

Meanwhile, told you it was a long one, I mix up some cleaning solution and as you can see I measure it precisely. The guys at 5 star chemicals will tell you that more isn't more, follow instructions precisely or you will either need to rinse more or find it doesn't do the job. Note: this is after the item has been cleaned of all visible dirt too. JMC has done a couple of great spreadsheets that anglicise the US instructions and put them into Excel, search on here for them. They are for PBW and Starsan and will ensure you always use the correct amount.

Once mixed up they go in the FV I am going to use with all of the post boil equipment as this is when it starts to get serious.

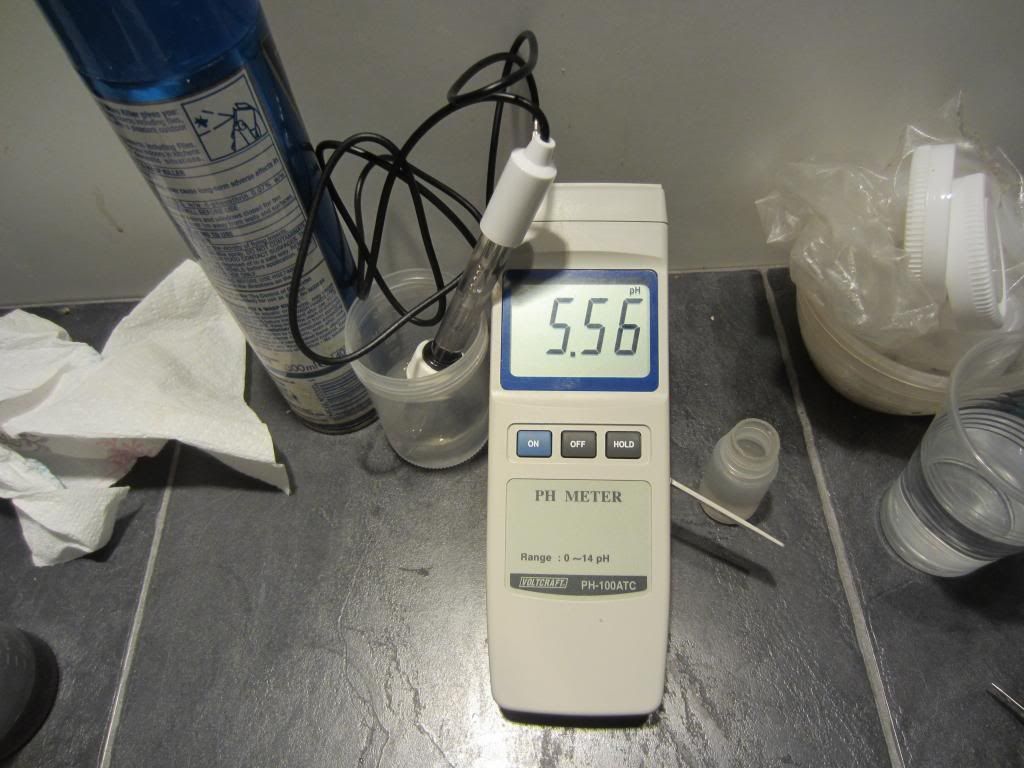

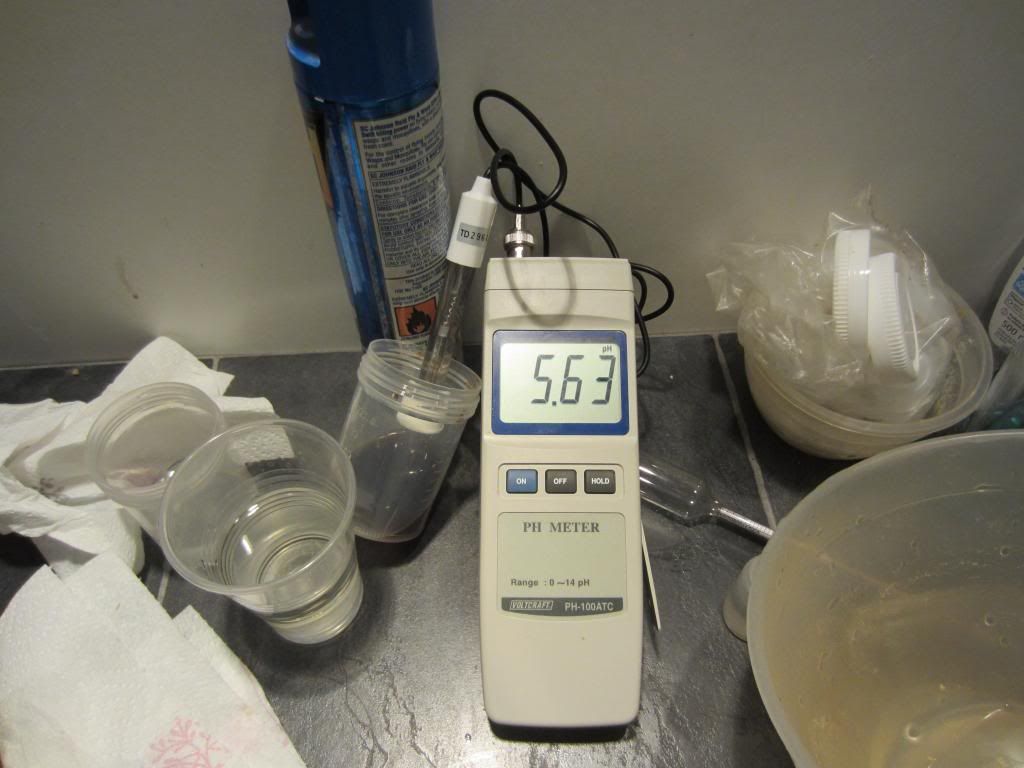

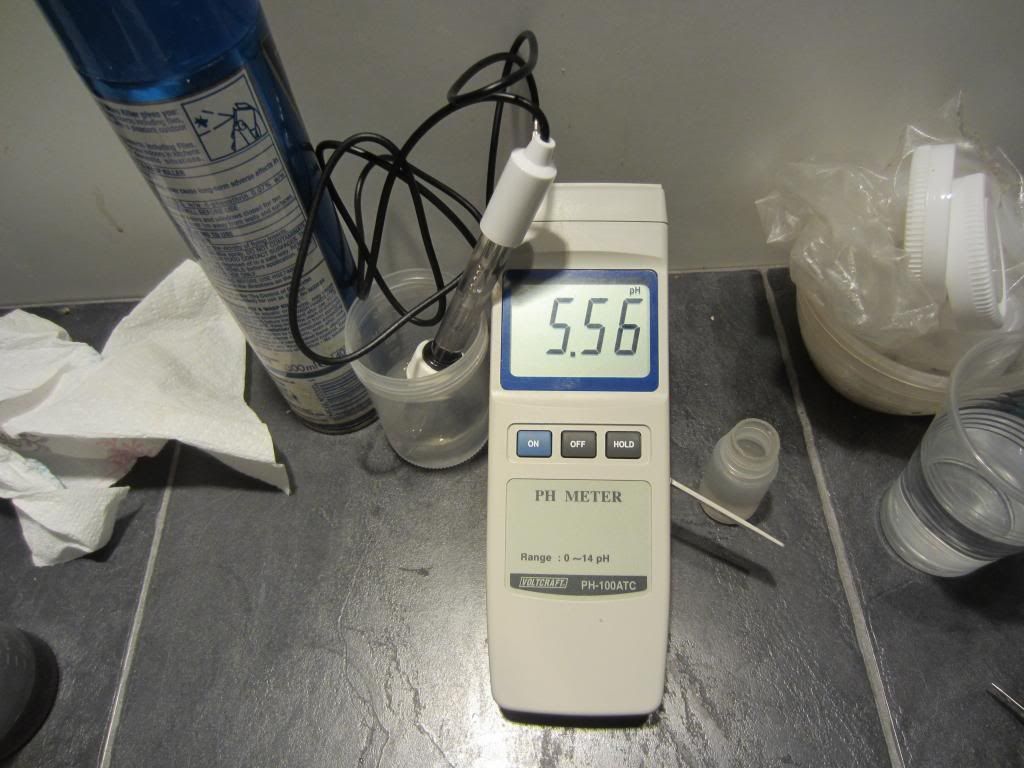

This shot shows me calibrating the pH meter, as you can see it is a little under the pH 7 point. Also note I am taking the temperature of the calibration solution to know what temp I need to have the samples at I will be testing later. I keep the calibration solution in the brew fridge at circa 20c so that I don't have so far to cool them.

As you can see here the post mash temperature is a lot lower than I originally was shooting for so I may end up with a slightly dryer beer than I was after, we shall see.

This is the start of recirculation. I usually jug about 8 litres of wort to get rid of as much grain as possible this is especially the case before I recirculate my pale ales using the solar pump as I want to ensure the minimum of grain is pushed through it.

I don't usually do this with my dark beers but thought I would take a picture to illustrate a point. When I usually jug a pale ale wort I use this BBQ tray pierced with holes to distribute the wort going back in so I minimise the disturbance of the grain bed. This is because I am after the clearest wort possible going into the boiler, I want to leave behind as much haze forming protein as I can. I like clear beer and if you can make it without then why not, it's not a lot of extra effort.

I fly sparge so I thought I would show a couple of things here, note that the tap on the MT is really throttled back, I'm after the slowest sparge and run off I can manage to maximise efficiency.

This shot isn't particularly clear but I was trying to show how much sparge water is above the grain bed, again designed to minimise disturbance and maximise the sugars being washed out, it also helps to keep the grain bed temp up.

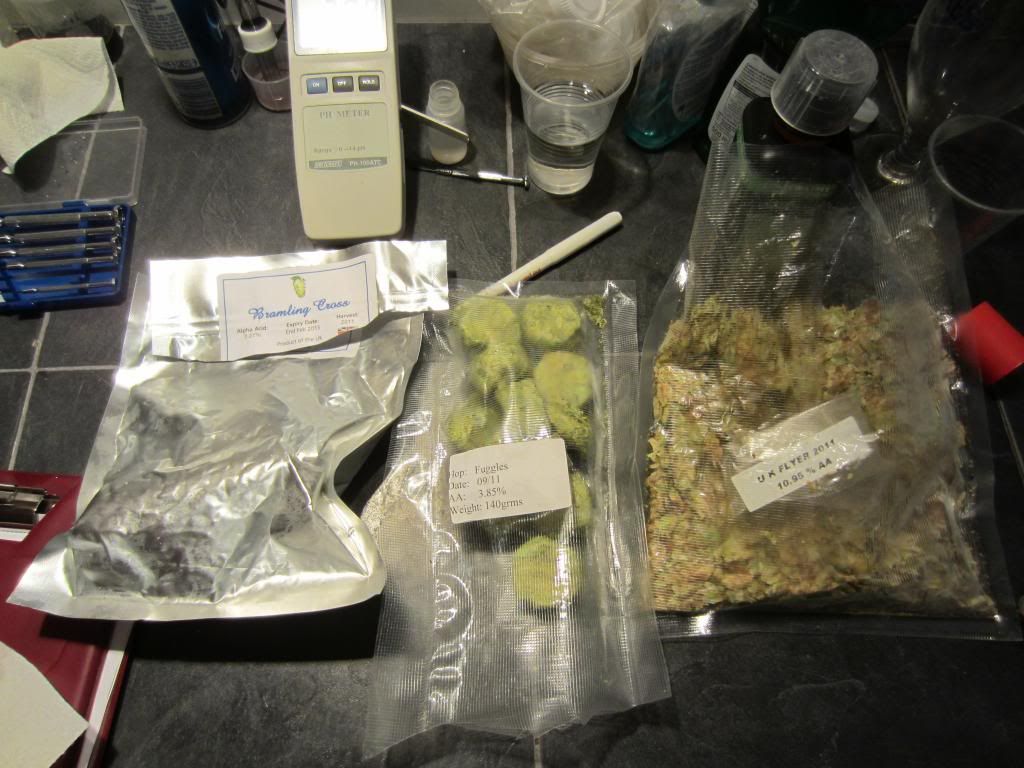

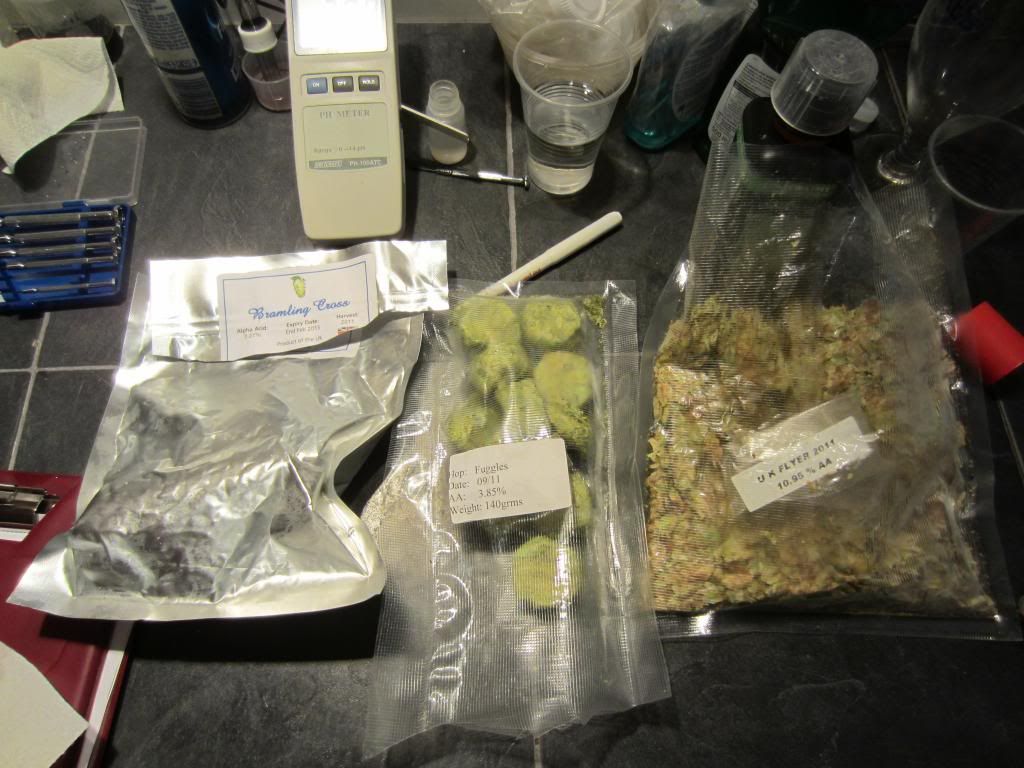

The hops being used. Shows a mixture of ones bought in the original packaging and ones I have repackaged. Note the Fuggles plugs, something I understand that is being phased out. They were originally designed to be easy to put into casks that were dry hopped before sealing.

I have decanted the wort off of the yeast and now keeping it at ferment temp so when beer is cooled to the same degree I can pitch immediately. In the back you can see the pH calibration solutions (7 & 4).

Possibly a controversial one this: I see beer making as essentially cooking. We work with recipes, weights, measurements, temperatures and times to produce a tasty, well dish of beer. When I make a stock I was always taught to skim all the shit that comes to the surface off of the stock so it didn't go back into it and "muddy" the flavours. So this is what's happening here. I honestly don't know if I'm wasting my time or not, but I think it helps, particularly in getting really clear pale beers. I find it aesthetically pleasing and it gives me something to do whilst waiting for the boil. You might argue that commercials don't do it so why should we. Well commercials do a lot of things we don't do and vice versa.

Boiling with virtually no "scum", this method is really useful if you are worried about boil overs when you are at the limit of your pot. I like to use both elements for the whole boil to get a decent break and good isomerisation of the hops. 2 elements would almost guarantee a boil over in a pot on the limit.

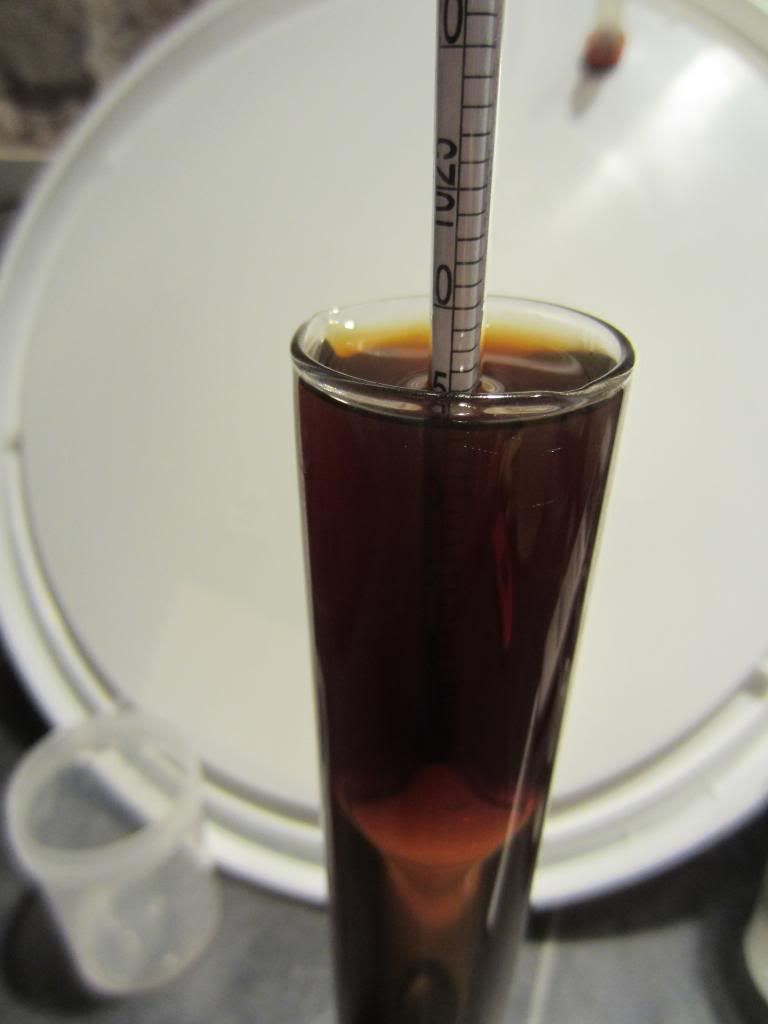

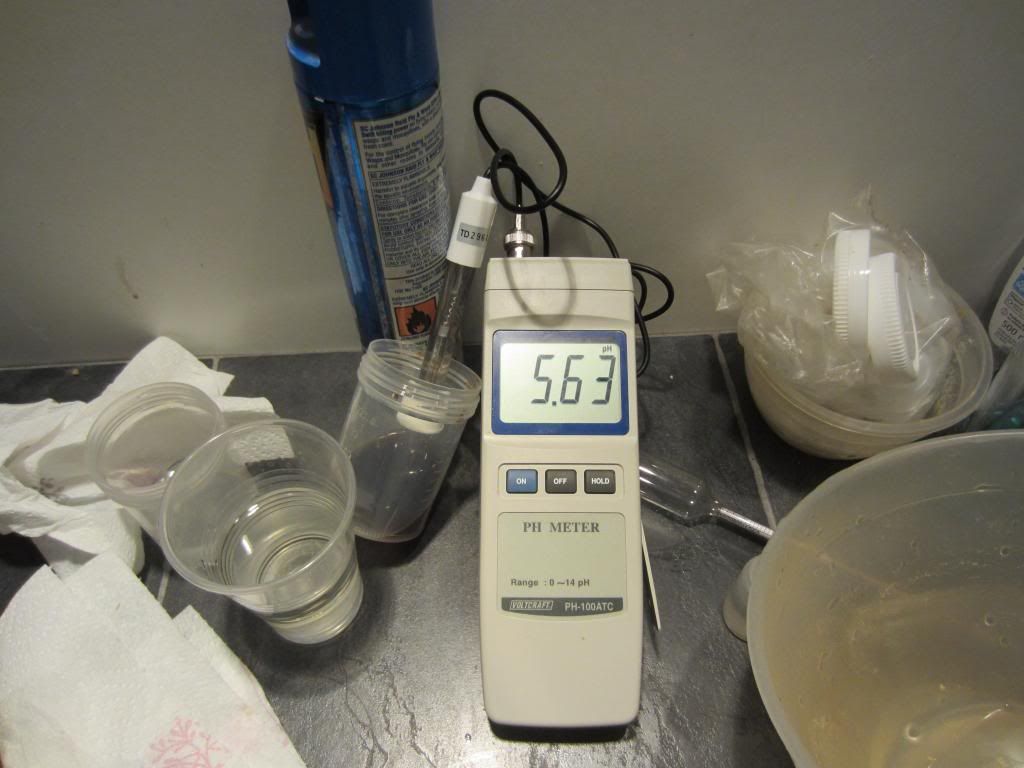

Alright time to get controversial again. I don't worry about sparging below 1.010 as I think that as long as your run off is below pH 6 at the end of collection you won't have a problem with tannins etc. This shot shows my sparge water was below pH 6 so I am confident the run off was below that, unfortunately I can't find a picture of the run off being measured so may have forgotten to take one. My notes tell me it was well under 6

Samples cooling for pre boil gravity taking, I don't trust hydrometer correction formulas, and next to it is my final runnings sample. I put them in the fridge to rapidly cool to circa 20c which is what the hydrometer is calibrated to and so is the pH meter.

This is the mash pH sample and as you can see it is way off the 5.5 I was aiming for. However, it is not an accurate picture. I mentioned earlier I had had to up the temp of the mash water in order to get it closer to the temp I was shooting for, this would have made a difference but, and here is the embarrassment, I also forgot to take the sample straight from the mash and took this from the run off so it's all a bit of a nonsense really

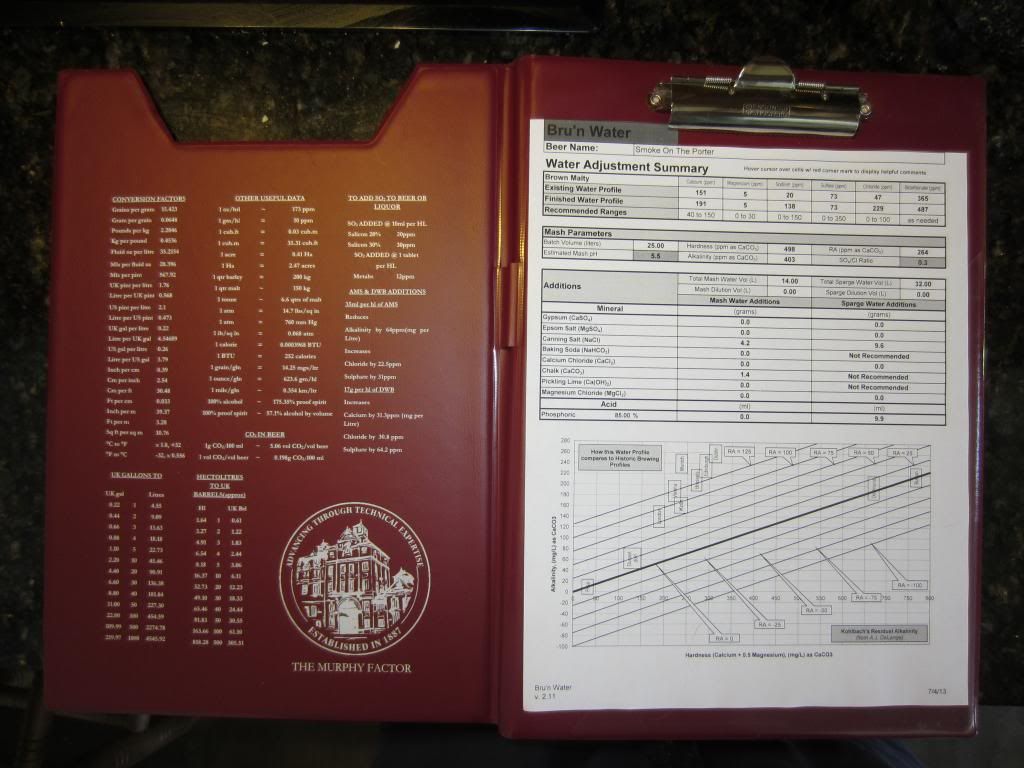

. I am confident in Brun' waters calculations so am reasonably happy I am in the ballpark.

As if I didn't have enough to do I even kegged an APA during the boil

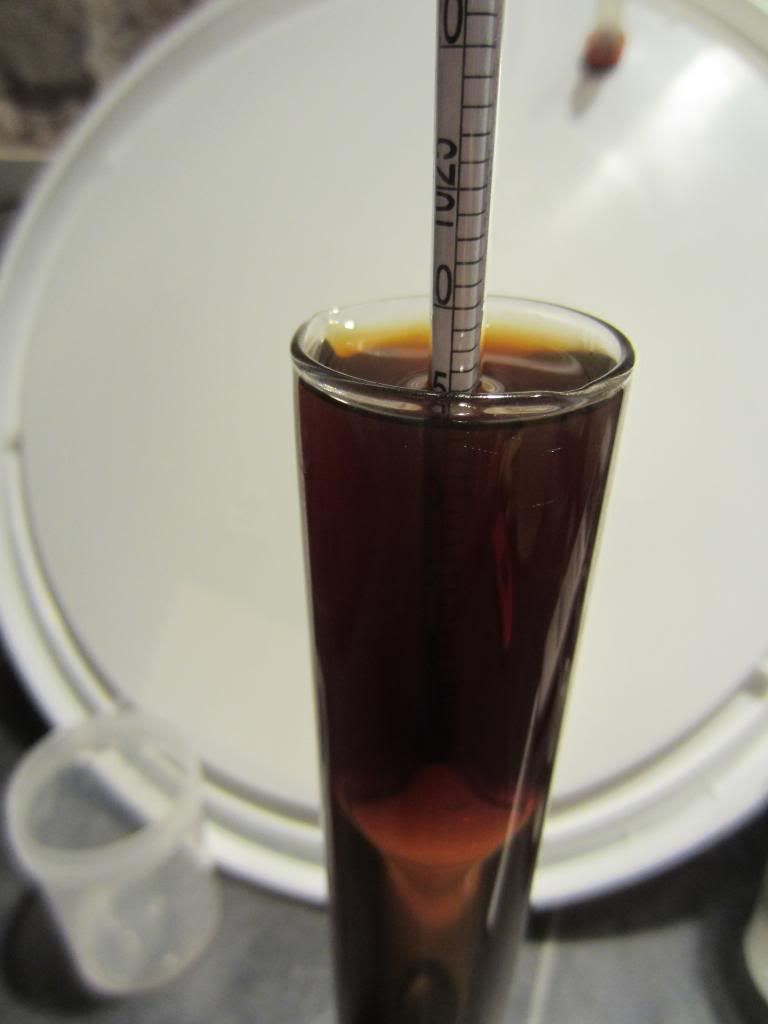

Pre boil wort SG using my final gravity hydrometer which is much more accurate than my standard hydro.

Immediately after switch off I hook up the plate chiller and begin cooling down the wort. No steep hops in this, which I have to be pretty quick with as the chiller pulls a massive amount of heat out of the wort right at the beginning. You can see that the solar pump is once again coming to the party.

This is how I cater for the "lost" water from the chiller. This pipe goes all the way up to the pond, which regularly needs topping up in hot weather.

This picture makes the earlier point about how fast the chiller works. The wort is over 95 c at this point and the groundwater is pushing 18-19 c.

Once at this point I am regularly checking the wort so as we get into temperatures that bacteria can survive at I need to be really careful with what goes in it. This is a handy tip, I keep the therma pen in starsan between tests.

That's a Blichman Thrumometer that does the job of monitoring temps really well too.

The money shot: This is with my standard hydro. What do you think it reads?

And now with the final SG one. Quite a difference I think

Immediately the chill is over I back flush the chiller with hot water for at least 5 minutes. This is then left to drain and then placed upside down in a 180 c oven for 1/2 hour. You wouldn't believe the gunk that comes out. I urge all plate chiller owners to try this. Put a tray directly under to make sure you don't confuse its gunk with the other gunk on the oven floor

I have often thought about getting an air diffusion stone etc but when you see what a paddle and a drill can do I'm not sure it's worth it.

Unfortunately trying to flame the flask holding the yeast flask and take a clear picture eluded me. Anyway the point is, you want the yeast flowing over a sanitised lip, just remember to spray a bit of starsan to cool it down or you fry your first billion cells

All tucked up: Now you may look at that and think "he only got 19 litres" but the rest is foam from the paddle aeration, told you it was good.

Always find dark beers are the filthiest, unfortunately for me my boiler has a lot of dead space but I don't really want that stuff as it tends to contain some of the stuff I'm trying to separate from the beer.

The famous hop sock, still wrapped around the copper manifold. The amount of crap this captures is unbelievable, but the wort going into the FV is crystal.

Cleans up lovely though, doesn't it?

And finally the scene of the "crime" after it was cleared up. I will do it properly after my holiday, honest

OK, phew that's it. Took almost as long to record it as to brew it. Bound to be a few things I've forgotten to mention and of course a lot of things that you will disagree with. I welcome all comments and queries so fire away.