You will need:

Battery drill

Good Cobalt drill bits 3.2mm http://www.ebay.co.uk/itm/190517612236? ... 1439.l2649 These are great - you wont need 10 but its good to have some backups and they are cheap.

Step bits http://www.ebay.co.uk/itm/400624040210? ... 1439.l2649

Cutting oil/wax (some people use WD40)

Blue masking tape - much better than the cheap paper white stuff

Pin punch and hammer

Finger metal file

Psychologist to answer 'why did i used to find this so damn hard to do'

I will drill two holes - one 32mm and one 14mm.

You will need to apply a fair bit of pressure (guide - half body weight) on to the drill so place your vessle on the ground. Turn it on its side and wedge so it cant move too much (good idea to put some cardboard down to protect it). Apply the tape and mark a center line.

Mark the two hole positions

Using a pin punch make a SINGLE hard strike to each hole position center

Set your drill to slow speed MAX torque

Dip drill bit in cutting oil. Position drill at center of hole apply half body weight and depress trigger - speed is the tricky bit, dont go too fast but also not too slow either or it wont cut. My best result is with my drill on its slowerst setting but full speed at that setting (bit less with step bits)

You can see we are starting to cut (little twirls of metal appearing, some nice hot metal noises). No rush, take a rest - apply some more oil. Continue

Just about to go through

Once through you can widen with more drill bits if you have them or move straight to a step bit

Put cutting oil on the step bit. Insert in the hole and off we go again. The step bit may jerk the drill, dont be scared but dont force it either. Bit of an action shot this so its blurred (heavy SLR in one hand drilling with the other !)

Every time the step bit drops up a step then stop drilling. Add more oil. Start drilling again.

Awwww we are nearly done, and i was enjoying it so much...

Peel the tape off and clean up. Need to remove all the burring or the seals will leak. Get a small file and file down on the inside AND out. Make sure your holes are lovely and smooth...only takes a minute.

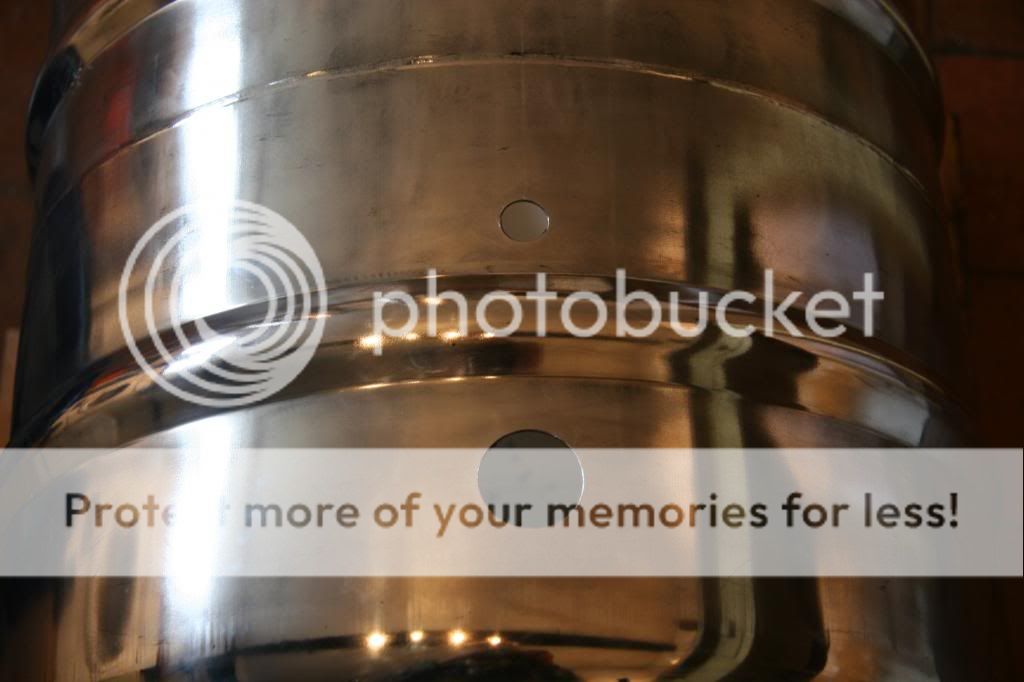

And there we have it, two gorgeous holes drilled in to a 1.8mm thick stainless keg

Remember: Cutting oil. Not too fast and not too slow. Dont be a whoosy, put some pressure on or you will work harden the steel making the job a lot harder.