PID Controller Enclosure Questions

-

Haydnexport

- Lost in an Alcoholic Haze

- Posts: 638

- Joined: Tue Jan 06, 2015 2:12 pm

Re: PID Controller Enclosure Questions

I'm about to order parts for one of these , is k1's diagram the way to wire it ? And what kind of isolation switch would I need. Could do with one of them gray enclosures too

Re: PID Controller Enclosure Questions

The switches I boughtHaydnexport wrote:And what kind of isolation switch would I need. Could do with one of them gray enclosures too

The enclosure I bought

YMMV for both though...

Cheers,

Bob.

I like beer --- Currently rebuilding the brewery, this time with stainless...

-

Graham

Re: PID Controller Enclosure Questions

[quote="k1100t"]Hello, I'm in the middle of gathering bits to build a PID controller for my HLT; which uses one of Mr Lard's 3KW elements. I've pretty much got everything, except for the terminal connectors, as I bought the wrong WAGO ones (two, instead of three). Searching for old posts to see how others have built theirs, leads me to a couple of questions:

1. Do I need to put a fuse on the 240V input to my enclosure? I wasn't planning on it, now I'm paranoid that I need one, but have no idea what type to get; normal 13A, some sort of fast blow, or which bit to put it on; input to the enclosure, between the PID and SSR, or between the SSR and the element.

2. I bought some 240V 15A DPDT switches to kill the element, but keep the PID live to use as a temperature sensor, but am now confused about where to put them. I've read that the SSR's can leak, so do I put the switch before or after it?

SSRs can leak; not enough to power the element or waste a significant amount of electricity, but enough to give you a jolt should you touch the live wire. Where you put the isolation switch probably doesn't matter much, as long as you are isolating the mains from the element. If there is any danger of anyone touching a wire or if a failure is lilely to result in any metalwork becoming connected, It is preferable to use a double-pole isolation switch, just in case someone wires a plug up the wrong way round. It sounds as if you were thinking of isolating the control input to the SSR, which is not direct enough in my view. A number of things can cause the thyristor to fire spontaneously for half a mains cycle, and that is enough to give someone a jolt.

1. Do I need to put a fuse on the 240V input to my enclosure? I wasn't planning on it, now I'm paranoid that I need one, but have no idea what type to get; normal 13A, some sort of fast blow, or which bit to put it on; input to the enclosure, between the PID and SSR, or between the SSR and the element.

2. I bought some 240V 15A DPDT switches to kill the element, but keep the PID live to use as a temperature sensor, but am now confused about where to put them. I've read that the SSR's can leak, so do I put the switch before or after it?

SSRs can leak; not enough to power the element or waste a significant amount of electricity, but enough to give you a jolt should you touch the live wire. Where you put the isolation switch probably doesn't matter much, as long as you are isolating the mains from the element. If there is any danger of anyone touching a wire or if a failure is lilely to result in any metalwork becoming connected, It is preferable to use a double-pole isolation switch, just in case someone wires a plug up the wrong way round. It sounds as if you were thinking of isolating the control input to the SSR, which is not direct enough in my view. A number of things can cause the thyristor to fire spontaneously for half a mains cycle, and that is enough to give someone a jolt.

- barneey

- Telling imaginary friend stories

- Posts: 5423

- Joined: Mon Jul 25, 2011 10:42 pm

- Location: East Kent

Re: PID Controller Enclosure Questions

Its been years since I built my control box viewtopic.php?f=6&t=50861&hilit=control+panel IIRC the PIDS controlled the SSR's, the SSR then obviously supplied the power to the element but there was an additional switched relay at the end before the connector to turn the supply either of or on. In additional to this I wired in the failsafe circuit, i.e. if anything was in the "on" position when the control box was switched on nothing would happen. All the diagrams needed are on the Electric brewer site.

Hair of the dog, bacon, butty.

Hops, cider pips & hello.

Name the Movie + song :)

Hops, cider pips & hello.

Name the Movie + song :)

-

bobsbeer

Re: PID Controller Enclosure Questions

Don't forget earth continuity in the wiring. That is the most important part. Yes when isolating you should isolate both live and return, but when connecting to metal vessels you need to ensure your earth is well and truly connected. So make sure you use twin earth cable to your elements and link all the earth lines in your box. If your box is metal then that too.

- themadhippy

- Even further under the Table

- Posts: 2970

- Joined: Tue Dec 08, 2009 12:53 am

- Location: playing hooky

Re: PID Controller Enclosure Questions

do you mean run 2 earth cables?if so why? 1 will do,or do you mean twin and earth cable? if so then NO twin and earth is most definatley not the cable to use,3 core 1.5mm flex ,HOF5 or 7 is my goto cable ,,and use a bit of silicon sleeving on the individual cores at the element end.So make sure you use twin earth cable

Warning: The Dutch Coffeeshops products may contain drugs. Drinks containing caffeine should be used with care and moderation

-

bobsbeer

Re: PID Controller Enclosure Questions

Depending on what is being wired, you may use cable. For the the connection to the element then you need flex. You still need an earth.themadhippy wrote:do you mean run 2 earth cables?if so why? 1 will do,or do you mean twin and earth cable? if so then NO twin and earth is most definatley not the cable to useSo make sure you use twin earth cable

Re: PID Controller Enclosure Questions

I was all ready to build the enclosure, when I read this thread...

I have a Draper ratchet crimping tool and a box of various red, blue and yellow connectors that came with it. I was planning on using these to do as much of the connecting inside the enclosure as possible, but am now unsure. I've also bought some 1.5mm^2 heat resistant flex, which I was planning on using to provide power to the enclosure and then onto the element. I was also planning on stripping the outer sheath off a length and using the internal insulated cores to do all the internal wiring (probably with blue connectors).

Is this a sane plan? Do I need to upgrade to 2.5mm^2 wire for the internal wiring? Will the Draper crimp connectors be good enough, or do I need to splash on better ones from RS or somewhere else...?

Thanks,

Bob.

I have a Draper ratchet crimping tool and a box of various red, blue and yellow connectors that came with it. I was planning on using these to do as much of the connecting inside the enclosure as possible, but am now unsure. I've also bought some 1.5mm^2 heat resistant flex, which I was planning on using to provide power to the enclosure and then onto the element. I was also planning on stripping the outer sheath off a length and using the internal insulated cores to do all the internal wiring (probably with blue connectors).

Is this a sane plan? Do I need to upgrade to 2.5mm^2 wire for the internal wiring? Will the Draper crimp connectors be good enough, or do I need to splash on better ones from RS or somewhere else...?

Thanks,

Bob.

I like beer --- Currently rebuilding the brewery, this time with stainless...

-

BenB

Re: PID Controller Enclosure Questions

1.5mm will do 14A which is more than the standard plug so no issue there unless the wires are insulated or packed closely. I'm not a fan of just crimping so tend to leave the wires slightly long so they extend a little onto the spade and solder- the solder will wick up into the crimp barrel.

-

bobsbeer

Re: PID Controller Enclosure Questions

I see no reason why your Draper ones won't work. Like Ben I prefer to solder my crimped connections.

- themadhippy

- Even further under the Table

- Posts: 2970

- Joined: Tue Dec 08, 2009 12:53 am

- Location: playing hooky

Re: PID Controller Enclosure Questions

why do people insist on soldering crimps?the clue is in the name,with a decent tool and the correct size crimp the connection will be just as good,if not better, in some places soldered connections aint allowed for mains connections but crimps perfectly aceptable

Warning: The Dutch Coffeeshops products may contain drugs. Drinks containing caffeine should be used with care and moderation

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: PID Controller Enclosure Questions

reading the link, it was a cheap automotive crimp tool used where Andy had problems, the ratchet type exert pressure over a wider area with broader jaws, if concerned they dont grip your flex, give it a good yank  IF you pull it out or feel movement perhaps consider doubling up the exposed wire mass inserted and redo

IF you pull it out or feel movement perhaps consider doubling up the exposed wire mass inserted and redo

Just checked Mrlards site for details of the element, that is if its rated at 3kw @220v 230v, or 240v?? I use the same elements But tbh this isnt something i have checked before.

Now i use 2.5mm flex to feed my elements, however the wiring within the power controller and Pid controller that they can connect to contains flex strands removed from 15a rated 1.5mm sq flex.

I do know that i draw current in my brewshed with a voltage just above 240v.

And I have had my controllers apart for mods and tweaks and to take the odd illustrating pic after they have had serious use, and I have had no hotspots charred insulator or burning issues, I do however mount heatsinks external to the box..

Just checked Mrlards site for details of the element, that is if its rated at 3kw @220v 230v, or 240v?? I use the same elements But tbh this isnt something i have checked before.

Now i use 2.5mm flex to feed my elements, however the wiring within the power controller and Pid controller that they can connect to contains flex strands removed from 15a rated 1.5mm sq flex.

I do know that i draw current in my brewshed with a voltage just above 240v.

And I have had my controllers apart for mods and tweaks and to take the odd illustrating pic after they have had serious use, and I have had no hotspots charred insulator or burning issues, I do however mount heatsinks external to the box..

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: PID Controller Enclosure Questions

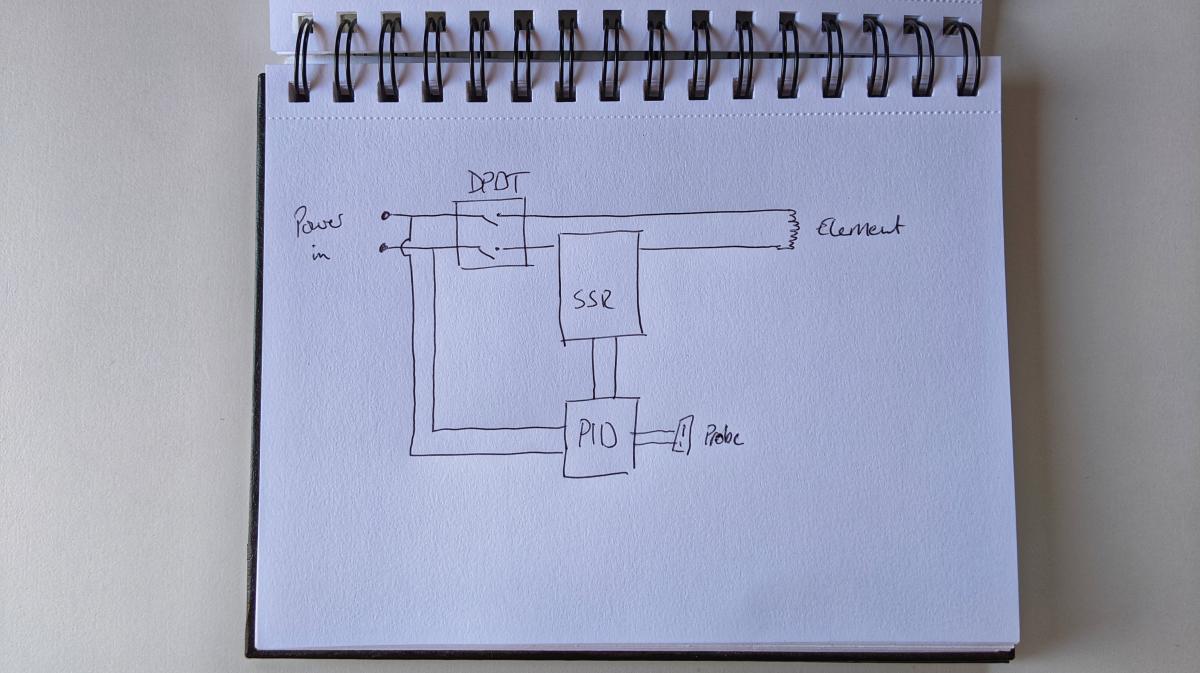

So... As I finished drilling all the holes in my stainless pots, the next thing on the list was to finally started building my HLT PID controller box. I appear to have deleted the image I created, of how it was going to be wired up though. So to save me from frying more electrics, I thought I should ask again, with another drawing. For the avoidance of doubt, I'm going with separate controller boxes for the HLT and boiler, rather than an all singing all dancing electric brewery a-like.

So, is this correct...?

The SSR is one of these, powering a Mr Lard 3KW element:

Controlled by an INKBIRD ITC-100:

I like beer --- Currently rebuilding the brewery, this time with stainless...

- themadhippy

- Even further under the Table

- Posts: 2970

- Joined: Tue Dec 08, 2009 12:53 am

- Location: playing hooky

Re: PID Controller Enclosure Questions

yep that looks fine ,dont forget the live (brown wire from the plug) is the one that goes to the ssr .And dont forget the earth,if its a metal box that needs to be connected to earth,as does the element

Warning: The Dutch Coffeeshops products may contain drugs. Drinks containing caffeine should be used with care and moderation

Re: PID Controller Enclosure Questions

Thanks! Was planning on drilling another hole in the back plate to mount a common earth bolt.themadhippy wrote: ↑Tue Apr 21, 2020 2:06 pmyep that looks fine ,dont forget the live (brown wire from the plug) is the one that goes to the ssr .And dont forget the earth,if its a metal box that needs to be connected to earth,as does the element

I like beer --- Currently rebuilding the brewery, this time with stainless...