Why didn't I think of thatbarneey wrote:Could you not make a boot for the keg, with one of orlando`s shoes?

23 litre cornie kegs, now sensibly priced??

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

But force carbonation doesn't take more than 30 psi? And I don't want to do that!jonnyt wrote:I'm thinking about these but am concerned that the pressure rating is 40 PSI whereas Cornies are rated above 130 PSI so a massive difference.

i.e. Is the stainless thinner and thus less robust?

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

-

jonnyt

Re: 23 litre cornie kegs, now sensibly priced??

Yes I know but it might be a testament as to the quality and durability of the product...

- Andy

- Virtually comatose but still standing

- Posts: 8716

- Joined: Fri Nov 18, 2005 1:00 pm

- Location: Ash, Surrey

- Contact:

Re: 23 litre cornie kegs, now sensibly priced??

Don't the "pukka" cornie lids also have an engineered weak area tab which would blow in the event of over-pressurisation ?

I didn't see this on the Chinese design.

Edit: looking at some google images I can see some lids with such a design and some without...

I didn't see this on the Chinese design.

Edit: looking at some google images I can see some lids with such a design and some without...

Dan!

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

Andy wrote:Don't the "pukka" cornie lids also have an engineered weak area tab which would blow in the event of over-pressurisation ?

I didn't see this on the Chinese design.

Edit: looking at some google images I can see some lids with such a design and some without...

Care to share? I can then have a close look and see if they do.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

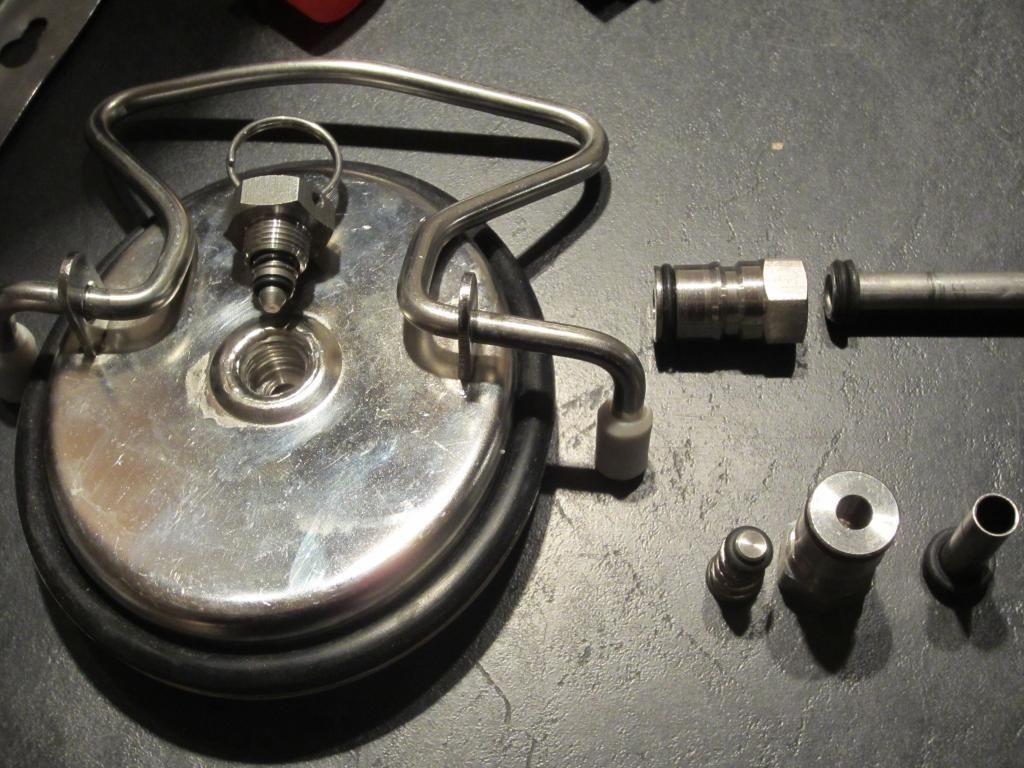

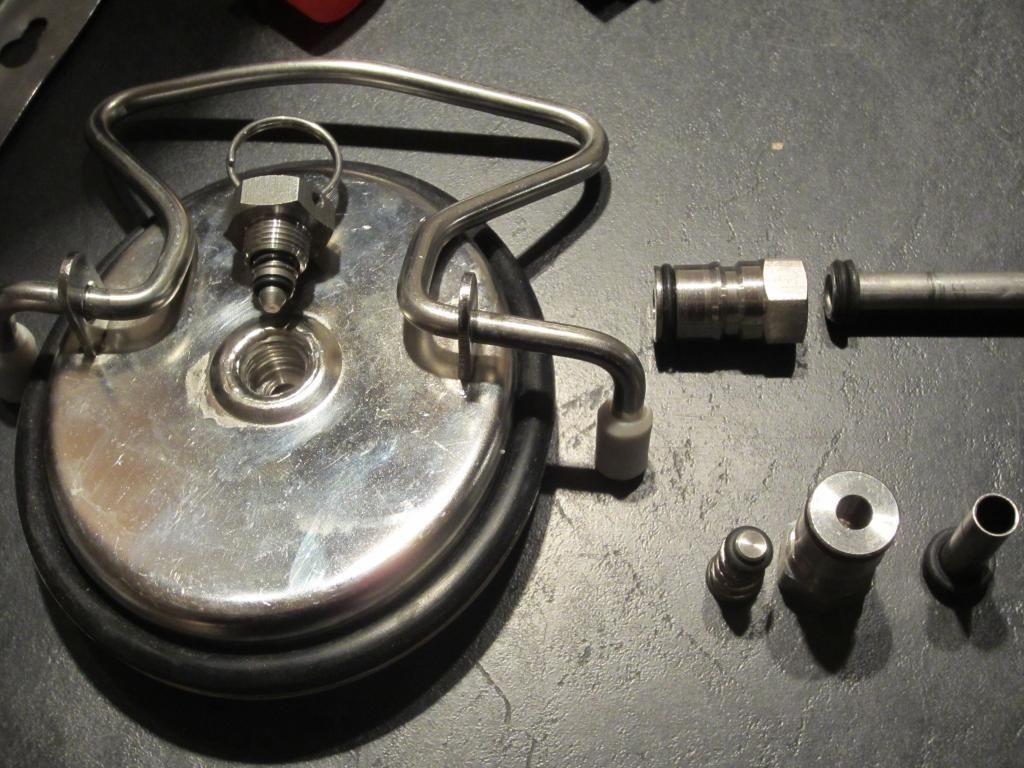

As this has generated quite a bit of curiosity over build quality I thought I would up load a couple more pictures.

I dismantled the two ball lock posts so you can see the dip tube and the gas inlet tube, along with the lid and removed safety release valve.

I have connected it up to my gas management board and will monitor the pressure to see if it manages to hold it properly.

I dismantled the two ball lock posts so you can see the dip tube and the gas inlet tube, along with the lid and removed safety release valve.

I have connected it up to my gas management board and will monitor the pressure to see if it manages to hold it properly.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

-

golden brewer

Re: 23 litre cornie kegs, now sensibly priced??

Orlando,

I have a 23 litre keg just like the ones you have purchased. I have had it four years without any problems. Mine has a sticker which says not to pressurise over 30 PSI which I have never found to be a problem. It has a pressure relief valve in the lid. I have never found a need to take the pressure up to 30 PSI. I have used this keg regularly over the four years for ales and lagers. I have never encountered any rust or pitting either.

I have another 8 Cornelieus 19 litre kegs that I use but the 23 litre keg is a great size and shape. Its height is less than the corny kegs so it fits better into a small fridge I have in my shed.

Overall I think you will be happy with them.

Cheers

I have a 23 litre keg just like the ones you have purchased. I have had it four years without any problems. Mine has a sticker which says not to pressurise over 30 PSI which I have never found to be a problem. It has a pressure relief valve in the lid. I have never found a need to take the pressure up to 30 PSI. I have used this keg regularly over the four years for ales and lagers. I have never encountered any rust or pitting either.

I have another 8 Cornelieus 19 litre kegs that I use but the 23 litre keg is a great size and shape. Its height is less than the corny kegs so it fits better into a small fridge I have in my shed.

Overall I think you will be happy with them.

Cheers

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

Encouraging Golden. I haven't come across a sticker on it but I believe the website says to only pressure up to 40 p.s.i. Like yourself I don't see me ever deliberately testing that, but of course can't rule out operator error!  There is a brew on tomorrow which is destined for one of the kegs and of course 3 more in quick succession

There is a brew on tomorrow which is destined for one of the kegs and of course 3 more in quick succession

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Re: 23 litre cornie kegs, now sensibly priced??

They look great mate. I've not got a technical/engineering opinion - but over the years using corny's and making lagers (which i know aren't your priority) i've never needed to pressurise above 15-18psi. they sound ideal. now if only i had the fridge space .... hehe.

Really like that gas management board too - is that an ebay purchase?

Really like that gas management board too - is that an ebay purchase?

-

daddies-beer-factory

Re: 23 litre cornie kegs, now sensibly priced??

Orlando,

I am thinking of going cornie keg instead of bottles, could you just run me through your procedure (post primary)

ie achieve finish gravity for a few days, - syphon into corny with cane sugar, inject co2, then store for 2 weeks at 20 degree, chill and serve ?

I am thinking of going cornie keg instead of bottles, could you just run me through your procedure (post primary)

ie achieve finish gravity for a few days, - syphon into corny with cane sugar, inject co2, then store for 2 weeks at 20 degree, chill and serve ?

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

Fuggledog wrote:They look great mate. I've not got a technical/engineering opinion - but over the years using corny's and making lagers (which i know aren't your priority) i've never needed to pressurise above 15-18psi. they sound ideal. now if only i had the fridge space .... hehe.

Really like that gas management board too - is that an ebay purchase?

I was having a discussion with Barneey about getting a corny keg set up and asking for advice on regulators and he sent a link to an Ebay auction for one identical to it. Unfortunately the auction had ended so I missed it he told me it was an auction Norm had started and suggested I contact him. Luckily he had a second one so I got a complete package from him, the kegs however had to come from the Home Brew shop as he didn't have any other than new 19l cornies. These were around £110, from memory, so the 23l ones are better value I thought.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

That is what I intend to do. I want to treat the cornies, as much as I can, as if they were a cask beer but I will fine and condition before placing it into them and am also interested in dry hopping them using a fine mesh hop bag containing pellets. I took delivery of the freezer yesterday so need to make up the collar for it, I already have the taps, tube heater and Barneey is making up an STC 1000 for me (daddies-beer-factory wrote:Orlando,

I am thinking of going cornie keg instead of bottles, could you just run me through your procedure (post primary)

ie achieve finish gravity for a few days, - syphon into corny with cane sugar, inject co2, then store for 2 weeks at 20 degree, chill and serve ?

I still intend to bottle as well as I find there are some beers that work particularly well in bottle and the little shelf that contains the freezers compressor can hold a dozen bottles of beer too.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

-

daddies-beer-factory

Re: 23 litre cornie kegs, now sensibly priced??

orlando wrote:That is what I intend to do. I want to treat the cornies, as much as I can, as if they were a cask beer but I will fine and condition before placing it into them and am also interested in dry hopping them using a fine mesh hop bag containing pellets. I took delivery of the freezer yesterday so need to make up the collar for it, I already have the taps, tube heater and Barneey is making up an STC 1000 for me (daddies-beer-factory wrote:Orlando,

I am thinking of going cornie keg instead of bottles, could you just run me through your procedure (post primary)

ie achieve finish gravity for a few days, - syphon into corny with cane sugar, inject co2, then store for 2 weeks at 20 degree, chill and serve ?) to control the temperature, I will also get a dehumidifier as I understand this is a hazard for keezers, the other thing to consider is a computer fan but as the freezer is quite small I'm going to see if I can keep a fairly consistent temperature throughout the "chamber" without it. A fly tipper dumped a load of Kingspan on some waste ground near here (

it's an ill wind...) so I can clad the inside of the collar to help with insulation. Got the first brew on to fill the first cornie so 3 more to go

I still intend to bottle as well as I find there are some beers that work particularly well in bottle and the little shelf that contains the freezers compressor can hold a dozen bottles of beer too.

Thanks Orlando,

One question, with cornies - do you need to store them for 2 weeks in the warm to get the carbonation going , or do you inject co2 and drink earlier ?

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: 23 litre cornie kegs, now sensibly priced??

You can do either. If you go for the latter you would want to make sure your beer is already crystal before putting it in the cornie because part of this method is to pressurise to something like 30 psi then shake the beer to force the CO2 into solution. Obviously this is then going to need to stand for awhile if any yeast has gone into the cornie. As I posted I want to go the "standard" route as I want the beer to follow a traditional CAMRA style of conditioning, if you have followed the thread from the start you will also see there have been concerns raised about the integrity of the kegs welds and their ability to withstand pressure much above 30 so it would seem to be prudent too.

I should find out in a months time when the current brew is coming into serving territory.

I should find out in a months time when the current brew is coming into serving territory.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer