Here it is.

Now the rest!

So at last brew day arrived . Finished work a little early and drove home like an axcited child….

This time an Ale with background in a recipe that was given to me by Furgus at Adnams,

The only change was from goldings to EK goldings which I understand to be the same thing.

In his comments regarding this beer furgus told me that the IBU is divided based on hop utilization at 3 different stages. A 1/3 at boil start, a ¼ at 10 minutes and the rest at 1 minute. He also told me that the most important was that the hops were to be the same by weight and not anything else. He told me that this beer varies ever so slightly from time to time.

So here comes the filth!

Mash on!

Temp here is at 64.5 and rising. It stopped at 66,6 so good enough for me.

And wrapped up for a nice 90 minute sleep whilst I caried on making a fence in the back garden.

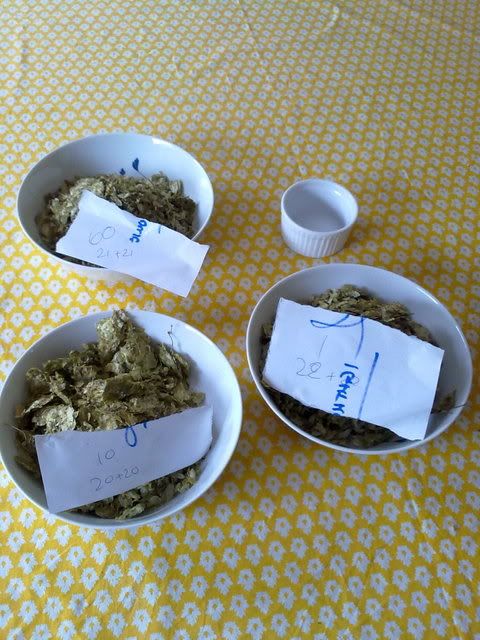

The hops. In total 116 grams ( 50/50 East kent and fuggles in each bowl.

For some reoason these really sucked up the wort and I ended up a little under the 25 litres I was hoping for.

The first runnings were very rich, I was a little surprised when you consider how litte dark crystal is actually in this batch as well, naturally it lightened a little during the sparge though.

After about 3 litres it ran clear and into the boiler it went.

The spent grain ready for the compost heap.

I was very anxious about the boil on this one, the packaging to my boiler says 36 litres capacity. I had 31 litres pre boil volume and can’t see how the other 5 litres would have had space. The hot break started to form, and the foam started to build…. My backside started to pout and I dared not look away from the pot just in case….. but, with paddle in hand I stired and the boil over never happened.

With 15 minutes to go the Ic went in , and with just a minute to go in went the last bundle of hops. By this time it smelled great in the kitchen. The neighbour stuck her head around the door and wondered what the smell was…..she said it smelled like sweaty feet. ( the cheek of it!)

The Wyeast 1335 started had fermented out and I decanted the fuild off and replaced with a litre of boiled and cooled wort. It started withing about 15 minutes, so all was well.

The cold break was actually huge, covered the elements in the boiler and these are placed at 9 and 10 litres respectively.

The run off from height gave great aeration again. The run off was clear after about 2 litres recirculated back into the boiler. In the end the foam was so much that I turned the tap off, this was a silly thing to do as I lost all the siphon effect that I had, meaning that with losses to trub etc I ended with 22.5 litre in the Fv and not the 25 I had planned.

Fermentation started within a couple of hours and yesterday there was yeast sitting all over the walls of the FV

OG was at 1042, and should have been at 1038, according to beersmith this gives me 83% efficiency so I am well pleased with this one, although I would have had more beer had I not turned the run off… off.

I added 2 litres of water to hit OG and this is fermenting really well- reading at 7 am this morning ( about 30 hours in,) and we are at 1014. target FG is 1010.

I am debating whether of not to dry hop this with something but am not sure. I travel offshore on Friday and will noot be back til the following Monday, so bottling will likey be in a week or so.

Any thoughts on the Dry hop? With what and how much for how long?

Thanks for reading.