Today was the day. So, a couple of pics to set the scene. Fuggles. On this first one, you can clearly see the yellow lupulin at the top of the cones

Here's the fuggles harvest. 1.209Kg, half a bin bag full, which would translate to about 300g dry - about 10oz. They'll do as aroma/flavour additions for a few brews (IPA's excepted

) It took about 1.5hrs with a pair of scissors to get 'em all.

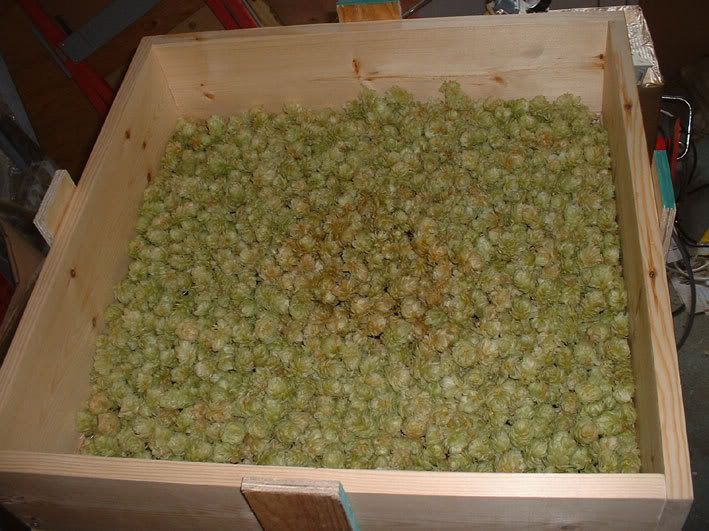

The Black Pig Brewery oast house

It's from 'The Homebrewer's Garden' by Joe & Dennis Fisher. It's two stackable boxes 2' square and 6" high each. The bottoms of the boxes are 13mm chicken wire. The top is 12mm ply with a hole in the centre for the hairdryer hose. The base is 12mm ply with sides of 3"x2" Cls timber (studwork timber). The sides of the base are drilled with 4 x 10mm holes each, to let the warm air out once it's percolated through the layers of hops. I finished building it today, having bought a lavatory flush pipe from the hardware shop which made a perfect duct for the hot air from the hairdryer to the oast. The hairdryer is Jen's granny hairdryer that I modified by removing the hood and using gaffer tape to seal around the hose. Set to 'warm' it produces a nice flow of air through the oast at around 55c. The preferred range is 45c-70c, so we're good there. The hops should be dry in 24hrs.

Inside the oast. The fuggles are in the lower box. Tomorrow I'll harvest the goldings and put them in the top layer if the fuggles aren't done by then.

Well, that was fun. The shed smells of hops, my hands were sticky with hop resin and the aroma from the bin bag of hops was lovely. So far so good. Once they're dry, it's into ziplock freezer bags, compressed, and into the freezer. As to wether it's worth it - the proof of the pudding will be when the home-hop beers are drunk.

Cheers,

Steve