...

Bottles from friends, I suspect they expect them returned full...

Get them de-labeled and in to a sanitizing mix...

The bottle tree I bought from http://www.the-home-brew-shop.co.uk is invaluable...

The Grolsch style bottles have the seals removed to sanitize seperately...

I have an open packet of sprey malt in a tupperware container to use as secondary fermentation fuel...

80 grams weighed out

And tipped into a mixing jug

Boiling water applied

and mixed... ahhh the smell...

Poured into (sanitized) secondary FV

All set up ready to transfer to FV2, reason being to mix secondary fermentation sugar (in this case spray malt) with beer before bottling...

I'm senile enough to have this wrong a few times, so make sure the container you're transferring to has the tap turned off. The "on - off" markings are also there becauase of past mistakes, laugh if you will...

The length of sanitized tibing will help for a aeriation-free transfer. Experts - am I right? you don't want oxygen in the mix at this stage?

For extra caution, a sanitized food-grade bucket below in case of disasters...

At this stage, the world will not implode if you steal a little taster...

Gently mixing the brew to distribute the sprey malt...

Attach the bottling stick to the secondary vessel and away we go...

I find if you fill to the top of the bottle, when removed from the volume displace by the bottling stick is just enough air gap...

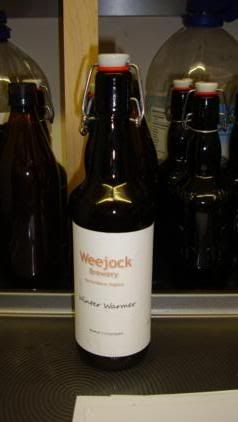

If you have more than one bottling on the go some kind of labeling ins needed

I find some childrens water-soluble gluestick works well, will wash off easily after use...

The finished bottle ready for conditioning

As always, comments and critism from the experts (and all you fellow beginners) welome.