50l Brewery Build

- floydmeddler

- Telling everyone Your My Best Mate

- Posts: 4160

- Joined: Mon Feb 16, 2009 10:37 pm

- Location: Irish man living in Brighton

Re: 50l Brewery Build

Do you have water butts? I'm planning on using 2 200L water buts to chill my wort down.

Re: 50l Brewery Build

Nope and we are trying to make use of as much existing gear as possible, we have set a rough budget for what we need, anything else will have to come later.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

-

Brighteyebeer

- Piss Artist

- Posts: 164

- Joined: Thu Mar 08, 2012 12:08 pm

- Location: East London

Re: 50l Brewery Build

Hi Kyle

Another thought on re-using your coolbox for post-boil cooling is to use it like a CFC. Roughly, that would involve:

Placing the coolbox between boiler and FV

Placing the copper coil in the coolbox

Connecting the coil to the boiler, and into the back of a ball valve, bulkhead connector or similar to run-off the wort into the FV

Fitting a drum tap to the coolbox. This connects a hose for outflow of cooling water

You then provide a constant flow of cold water from the tap via a hose.

This gets round the issue of whether the coolbox would hold enough coolant to do the job. Cost of fittings would be offset by not needing a pump. Just a thought.

Cheers,

Chris

Another thought on re-using your coolbox for post-boil cooling is to use it like a CFC. Roughly, that would involve:

Placing the coolbox between boiler and FV

Placing the copper coil in the coolbox

Connecting the coil to the boiler, and into the back of a ball valve, bulkhead connector or similar to run-off the wort into the FV

Fitting a drum tap to the coolbox. This connects a hose for outflow of cooling water

You then provide a constant flow of cold water from the tap via a hose.

This gets round the issue of whether the coolbox would hold enough coolant to do the job. Cost of fittings would be offset by not needing a pump. Just a thought.

Cheers,

Chris

Re: 50l Brewery Build

Hello Chris,

I quite like that idea, saves money and serves a purpose, would have to check the tap fitting as I think it is just a smooth bore on the inside of the tank connector but I shall certainly have a think on that, kind of like a giant plate chiller, only cheaper.

Cheers

Kyle

I quite like that idea, saves money and serves a purpose, would have to check the tap fitting as I think it is just a smooth bore on the inside of the tank connector but I shall certainly have a think on that, kind of like a giant plate chiller, only cheaper.

Cheers

Kyle

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Another little update,

The new 38.5l mash tun is ready to rumble from Powell Brewing, lovely chap sorted out an addition couple of bits for me, just waiting for it to be shipped, the furniture is in the garage just need to square it up and position it properly.

After that we should be all good for ordering the new boiler and the fittings, will take some pics as bits arrive and get put together.

Cheers

Kyle

The new 38.5l mash tun is ready to rumble from Powell Brewing, lovely chap sorted out an addition couple of bits for me, just waiting for it to be shipped, the furniture is in the garage just need to square it up and position it properly.

After that we should be all good for ordering the new boiler and the fittings, will take some pics as bits arrive and get put together.

Cheers

Kyle

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Next update:

The mash tun should arrive tomorrow and the bloke soldered on a copper syphon to reduce the deadspace to a minimum, will also pick up the sparge arm I ordered from the home brew shop and have a look at that, will post up some pictures tomorrow when I pick it up.

Came across the Minibrew 15 gallon conical fermenter, anyone know anything about them?

Cheers

Kyle

The mash tun should arrive tomorrow and the bloke soldered on a copper syphon to reduce the deadspace to a minimum, will also pick up the sparge arm I ordered from the home brew shop and have a look at that, will post up some pictures tomorrow when I pick it up.

Came across the Minibrew 15 gallon conical fermenter, anyone know anything about them?

Cheers

Kyle

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

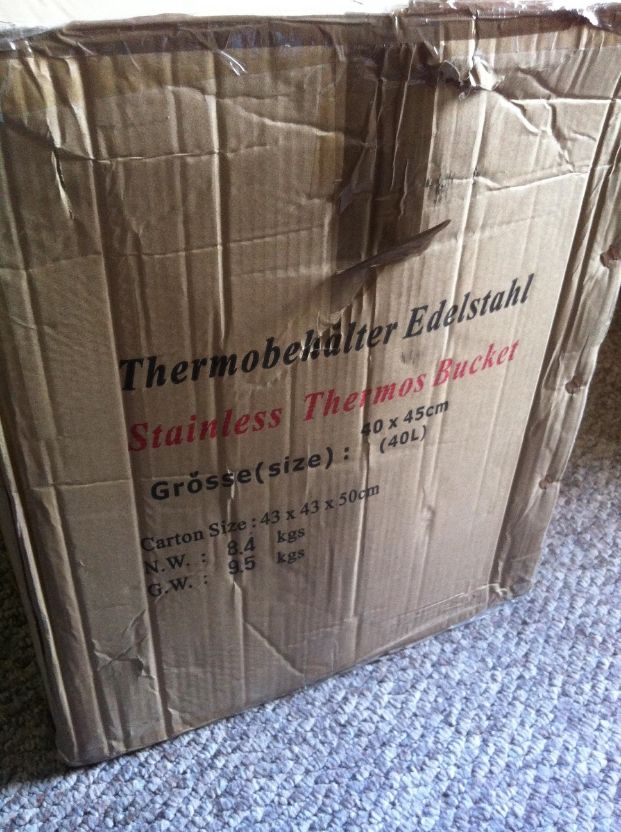

Hello all,

Both of the items arrived today and I must say I was like a kid in candy shop! I will have to bodge job the sparge arm a little as the whole drilled in the plastic is bigger than the shaft of the sparge arm so it rattled around whenever I moved it.

The Thermopot is lovely, can't fault it at the moment, no damage, lovely false bottom and the guy soldered in a copper siphon to reduce the dead space, a very quick test left me with 2.7L of it at the end.

Here are the photos:

Enjoy.

Cheers

Kyle

Both of the items arrived today and I must say I was like a kid in candy shop! I will have to bodge job the sparge arm a little as the whole drilled in the plastic is bigger than the shaft of the sparge arm so it rattled around whenever I moved it.

The Thermopot is lovely, can't fault it at the moment, no damage, lovely false bottom and the guy soldered in a copper siphon to reduce the dead space, a very quick test left me with 2.7L of it at the end.

Here are the photos:

Enjoy.

Cheers

Kyle

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

- floydmeddler

- Telling everyone Your My Best Mate

- Posts: 4160

- Joined: Mon Feb 16, 2009 10:37 pm

- Location: Irish man living in Brighton

Re: 50l Brewery Build

Nice!

Re: 50l Brewery Build

Fellow ladies and gentle brewers!

I give you the first sneak peak photograph on the new brew system build:

Enjoy:

Kyle

I give you the first sneak peak photograph on the new brew system build:

Enjoy:

Kyle

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

- floydmeddler

- Telling everyone Your My Best Mate

- Posts: 4160

- Joined: Mon Feb 16, 2009 10:37 pm

- Location: Irish man living in Brighton

Re: 50l Brewery Build

You're going to have the time of your life Kyle!

Re: 50l Brewery Build

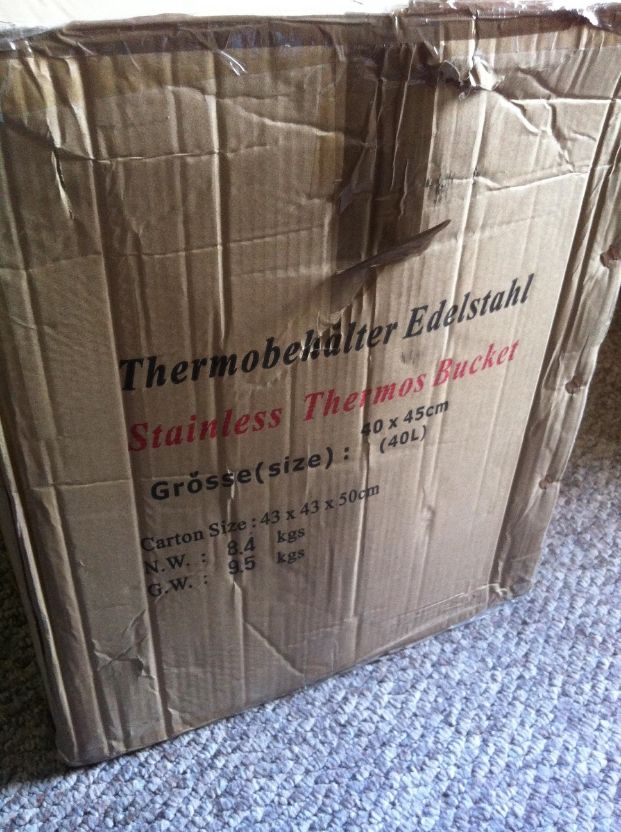

Little update for everyone:

The last vessel has arrived this morning with a couple of the fittings, will get everything lines up for a group photo an will work out what we have left to buy. Shouldn't be too long.

Kyle.

The last vessel has arrived this morning with a couple of the fittings, will get everything lines up for a group photo an will work out what we have left to buy. Shouldn't be too long.

Kyle.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Hello all

After being away for the weekend at a festival I have returned to upload the next picture of the build, all the vessels are together and to save a little time to get brewing we are just buying a few fixtures and fittings and will lift the wort the old way.

Maybe next month we will look at buying the pump and everything to reduce labour, plans are for Thursday to fit the boiler element, order the remaining fittings and run a water test with the sparge arm in place.

Cheer

Kyle

After being away for the weekend at a festival I have returned to upload the next picture of the build, all the vessels are together and to save a little time to get brewing we are just buying a few fixtures and fittings and will lift the wort the old way.

Maybe next month we will look at buying the pump and everything to reduce labour, plans are for Thursday to fit the boiler element, order the remaining fittings and run a water test with the sparge arm in place.

Cheer

Kyle

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Hello again all.

After doing some cold water tests as there wasn't much else to do at this point, we discovered my HLT element has started leaking so that is a job added to the list. The sparge arm worked wonderfully up until it had 14 litres remaining in the HLT, then it stopped, I was lucky enough to be invited to visit GrowlingDogBeer's brew set up and it clearly showed we had nowhere near enough height to produce the gravity we needed to drain the tank.

So, now we have to build a suitable shelf for it to sit on about 2ft above its original position as well as to stop the leaking element. The MT worked like a charm but we have also decided to invest in some camlock fittings and silicone tube, alongside the pump and other bits that shall be ordered at the beginning on the new month.

Another job on the to-do list is retro fit a sight glass to the HLT to save climbing up a ladder to dipstick the liquor, we will also be putting the gas burner back together and use that for the boiler instead of fitting another element as we have yet to install the new socket in the garage and I have a gas bottle sitting unused.

Will post up a couple of pictures of the water test later on. My poor pocket has yet to breathe a sigh of relief after the last few months burning it's suffered.

Cheers.

After doing some cold water tests as there wasn't much else to do at this point, we discovered my HLT element has started leaking so that is a job added to the list. The sparge arm worked wonderfully up until it had 14 litres remaining in the HLT, then it stopped, I was lucky enough to be invited to visit GrowlingDogBeer's brew set up and it clearly showed we had nowhere near enough height to produce the gravity we needed to drain the tank.

So, now we have to build a suitable shelf for it to sit on about 2ft above its original position as well as to stop the leaking element. The MT worked like a charm but we have also decided to invest in some camlock fittings and silicone tube, alongside the pump and other bits that shall be ordered at the beginning on the new month.

Another job on the to-do list is retro fit a sight glass to the HLT to save climbing up a ladder to dipstick the liquor, we will also be putting the gas burner back together and use that for the boiler instead of fitting another element as we have yet to install the new socket in the garage and I have a gas bottle sitting unused.

Will post up a couple of pictures of the water test later on. My poor pocket has yet to breathe a sigh of relief after the last few months burning it's suffered.

Cheers.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Thanks for the update, very interested in this as I'm doing a build too.

Sabro Single Hop NEIPA 25/02/20 CLICK ME to monitor progress with Brewfather & iSpindel

Re: 50l Brewery Build

No worries, it has been a fairly quiet week in terms of actually getting things done and I have changed the original plan slightly, but with the camlock fittings it will make it easier in the long run.

Also need to buy a 14mm QMax cutter and 15mmx8mm compression adaptor to put on the sparge arm to take the 1/2" tubing.

Also need to buy a 14mm QMax cutter and 15mmx8mm compression adaptor to put on the sparge arm to take the 1/2" tubing.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com