50l Brewery Build

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: 50l Brewery Build

step drills are ok for opening up smaller diameter holes, but become easy to burn out with larger ones in SS.. for low pressure and non load bearing fittings u can substitute fat silicone orings x1 x2 ? (ebay china..) for olives in compression fittings to seal slightly undersized tubing

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: 50l Brewery Build

If I find a step drill locally that I can pick up for cheap I will probably use that option. The compression fitting is to attach a camlock disconnect to so I can pop the tube off the under let and just connect it up to the sparge arm when needed. Well, that's the general idea.

EDIT:

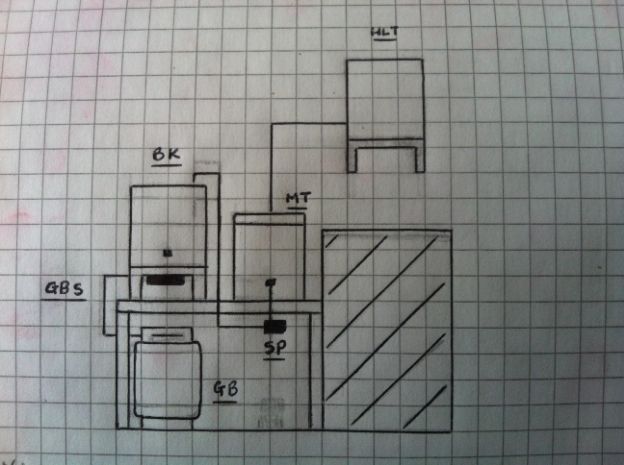

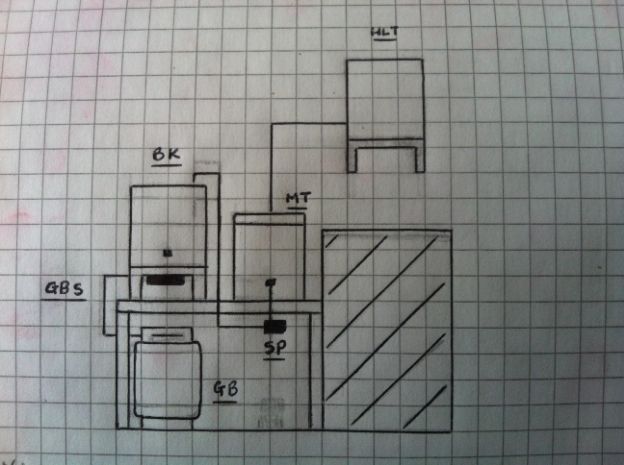

As promised, here are the couple of photos I took during the first water test, not a very good picture inside the mash tun but it gives you the idea and a nice view of the false bottom, the other was just measuring the flow rate and the last one is the new plan idea based on what we learn't from GrowlingDogBeers and a reshuffle to avoid cause problems with the garage door.

So much to do and such little time but it certainly been a good learning experience so far.

Cheers.

EDIT:

As promised, here are the couple of photos I took during the first water test, not a very good picture inside the mash tun but it gives you the idea and a nice view of the false bottom, the other was just measuring the flow rate and the last one is the new plan idea based on what we learn't from GrowlingDogBeers and a reshuffle to avoid cause problems with the garage door.

So much to do and such little time but it certainly been a good learning experience so far.

Cheers.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: 50l Brewery Build

a couple of things i learnt the hard way using camlocks, dont forget any volume in the tube when it comes to disconnecting from a low down fitting... and if hot liquor is flowing thru a camlock joint the fitting will get hot so a rag, towel, and bucket are crucial bits of kit

while Mrlard is now selling wider bore hosetailed camlocks if u up the silicone hose size to 17-19mm id, cheap 1/2" weld nipples 19-20mm od will make female threaded camlocks full bore jobs (with a jubilee clip..)

(with a jubilee clip..)

while Mrlard is now selling wider bore hosetailed camlocks if u up the silicone hose size to 17-19mm id, cheap 1/2" weld nipples 19-20mm od will make female threaded camlocks full bore jobs

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: 50l Brewery Build

That is basically what we are after, removes the need for a wort bucket and I found an old Hornby controller to control the flow. We're going with the regular bore camlock fittings for now, can't really see the need for a larger bore on such a small system, no particular rush to transfer.

I can understand the rag and towel but what's the bucket for?

I can understand the rag and towel but what's the bucket for?

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: 50l Brewery Build

to catch any volume contained in the hose when disconnected, if using your system as per the sketch and u underlet to fill your tun, closing both valves will capture a volume of liquid in the hose, without extra valves on each end of the hose this will spill somewhere when disconnected a bucket helps catch this waste liquor..Kyle_T wrote:

I can understand the rag and towel but what's the bucket for?

And its inevitable u will start filling one vessel one day with its drain valve open, hanging a bucket on the valve of any vessel u fill is a good idea, u check the valve as u hang the bucket - belts n braces - NO SPILLS

Re: 50l Brewery Build

Ah I get what you mean, logical thinking, I like it! How hot does one of those little pumps get on full pelt?

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: 50l Brewery Build

pretty good, at about 8v supplied it pushes a flow of upto 3l per min up 1.5m thru 7+m of cf chiller with a 9.5mm internal bore

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: 50l Brewery Build

Always handy to know, I shall be looking to draw it on as low a voltage as possible just to see how it draws from the mast tun tap compared to the inflow from the sparge arm.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Are you not using a plate chiller Kyle?Kyle_T wrote:Always handy to know, I shall be looking to draw it on as low a voltage as possible just to see how it draws from the mast tun tap compared to the inflow from the sparge arm.

Sabro Single Hop NEIPA 25/02/20 CLICK ME to monitor progress with Brewfather & iSpindel

Re: 50l Brewery Build

No mate, bit of a luxury for me at the moment, spending enough on this build as it is lol. The immersion coil does a good enough job, probably wouldn't look at a plate chiller until I hit 70l vessels or 100l. And some seem to say they are a bigger pain for cleaning and sterilising, but I imagine that is more personal experiences.

One thing I am looking at is a few ways to recirculate the cooling water with my old mash tun and a pump, but that will come at a later stage, our gear has already laid dormant for 6 weeks and I'm getting itchy to brew again.

Cheers.

One thing I am looking at is a few ways to recirculate the cooling water with my old mash tun and a pump, but that will come at a later stage, our gear has already laid dormant for 6 weeks and I'm getting itchy to brew again.

Cheers.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Ok mate, my budget it getting stretched too.

So you are pumping from the tun into your boiler?

So you are pumping from the tun into your boiler?

Sabro Single Hop NEIPA 25/02/20 CLICK ME to monitor progress with Brewfather & iSpindel

Re: 50l Brewery Build

Yes mate, we were originally going to have a wort bucket under the valve of the mash tun, using an elbow fitting and hosebarb to direct the flow, the bucket itself having a bulkhead fitting and hosebarb to connect via a small section of silicone tubing to the pump, but from lessons learnt and convenience sake, we will just fit a camlock fitting to the tun tap and use camlock fittings on the pump.

It will also allow us to quickly connect the HLT to the tun to do the under letting and a quick change after the mash to draw the wort for the sparge, coupled to a variable voltage controller we should be able to achieve a pretty low flow rate so we don't exceed the flow rate of the sparge arm.

Hope that makes sense.

It will also allow us to quickly connect the HLT to the tun to do the under letting and a quick change after the mash to draw the wort for the sparge, coupled to a variable voltage controller we should be able to achieve a pretty low flow rate so we don't exceed the flow rate of the sparge arm.

Hope that makes sense.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: 50l Brewery Build

When u jug back before u start a fly sparge, gauge the maximum natural flow from the tun by counting off seconds while it fills 1l of your jug.

if your batch sparging, i would avoid the pump and drain each batch into a fv, if weight is an issue u can submerge a clean pump in the liquor to pump at full pelt into the kettle, but with batch sparging the drain slows as the tun empties and could be very difficult to match in sync with pumping speed.

if your batch sparging, i would avoid the pump and drain each batch into a fv, if weight is an issue u can submerge a clean pump in the liquor to pump at full pelt into the kettle, but with batch sparging the drain slows as the tun empties and could be very difficult to match in sync with pumping speed.

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: 50l Brewery Build

It will be a fly sparge jobby for now, haven't played around with batch sparging just yet. As much as I would love a mini-mag pump, at twice the price on top of what I've already paid, it will have to wait a little while, the good part is I can still do the sparge the old fashioned way should it all go wrong.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com

Re: 50l Brewery Build

Update:

Have spoken with Mr Lard and placed a rather hefty order for the remaining fixtures and fittings including a sight glass and pump. Just waiting for the rest of the process to finish so it can be delivered.

The gas bottle and burner are waiting to be taken over and the burner reconnected to the stand. The wood is ready for making up and then it's just a case of fixing it together, all we need now is the compression adaptor and cutter for the sight glass then we can run a proper water test to fix any leaks. Got some PTFE ready to go.

Would just like to say thanks to all for the interest, advice and comments so far.

Cheers.

Have spoken with Mr Lard and placed a rather hefty order for the remaining fixtures and fittings including a sight glass and pump. Just waiting for the rest of the process to finish so it can be delivered.

The gas bottle and burner are waiting to be taken over and the burner reconnected to the stand. The wood is ready for making up and then it's just a case of fixing it together, all we need now is the compression adaptor and cutter for the sight glass then we can run a proper water test to fix any leaks. Got some PTFE ready to go.

Would just like to say thanks to all for the interest, advice and comments so far.

Cheers.

My Ridleys' Brewery Blog:

http://www.theessexbrewer.wordpress.com

http://www.theessexbrewer.wordpress.com