Is it best to have the drain in the centre of the pot or as close to one edge, I was thinking if in the centre it might create a more even flow through the grain bed maybe slighly better efficency, or if close to the edge pot could be angled slightly to to get more wort out?

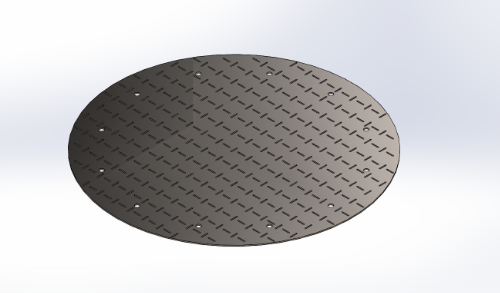

Im going to make my own false bottom im thinking either 16swg or 18swg (1.5mm or 1.2mm) Stainless steel CNC punched out with a pattern of small slots 12mm x 1.5mm Is it best to have a small area below the false bottom or a larger void or does it really not matter how high I space it from the bottom, the holes are where i would put some M6 Button head screws to hold spacers on the bottom, probably put some more closer to the middle to support the weight of the grain too, but just an idea at the moment

I may go for a herms or rims set up in the future would there be any advantage in having a separate port in the bottom for that