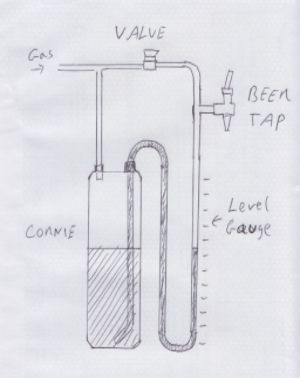

Basically, you loop the beer line to the bottom of the cornie and back up again on its way to the tap, then connect the gas line from the opposite direction via a valve. Usually this valve is off and you can pour the beer as normal. When you want to check the beer level, you simply open the valve, and the beer level in the beer line will equalise with the beer level in the cornie.

I tried it on my latest batch and it seems to work. Apologies for the crap photo, but at least you can see the beer level in the beer line.

Advantages are that it only takes a couple of extra John Guest fittings, and since many of us have a few feet of beer line coiled up in the beer fridge already it might as well be put to use. Disadvantages might include the fact that every time you check the beer level, you are returning a few ml of beer to the cornie, which could stir up the sediment and so on. And I suspect it might not work at low gas-pressure levels, since the friction in the beer line would prevent the beer from self-levelling accurately.

Anyway, apologies if everyone's doing this already, but I hadn't come across it before, and it seems easier than messing around with floating magnets and so on.