Filtering beer

- HTH1975

- Piss Artist

- Posts: 224

- Joined: Sat Aug 12, 2017 8:24 pm

- Location: Thirsk, North Yorks (ex-pat Geordie)

Re: Filtering beer

There are a few key processes I find that are important to clear beer, and you really need to be getting your beer clear as possible at each stage (imo).

* recirculate your mash - I've found that recirculating with a pump in the last 15 minutes gives me a clear wort with no 'bits' transferred to the boil kettle. I used to recirculate all through the mash, but found I lost too much temperature.

* a good strong, rolling boil

* Irish moss during the last 15 minutes. I found that the loose Irish moss worked better for me than protofloc tablets. It was a noticeable improvement in clarity.

* people say that quick chilling is key to a good cold break and therefore clearer wort. I've never not done this, so have no empirical evidence. I just do it as I need my wort at a temperature suitable for pitching the yeast.

* whirlpool after chilling and leave the wort to settle for 30-60 minutes. I find that the wort will naturally settle out during this time and I get very clear wort into the FV.

As for post-fermentation. Just be patient and it will clear. I've got a beer that had all kinds of fruit in the secondary and had no right to be clear. I just left it in my cellar (forgot about it in truth) for 3-4 months. Just bottled it last week and it's crystal clear. I always use Saf bottling yeast (1g per 25L is more than enough). It sets tight and you get clear beer from the bottle.

That's pretty much my key steps and it works for me.

I do treat my brewing liquor and have a good dose of DWB and calcium in the mash tun, plus AMS to soften the water a little. I've also started adding a 1/2 tsp calcium to the boil recently.

* recirculate your mash - I've found that recirculating with a pump in the last 15 minutes gives me a clear wort with no 'bits' transferred to the boil kettle. I used to recirculate all through the mash, but found I lost too much temperature.

* a good strong, rolling boil

* Irish moss during the last 15 minutes. I found that the loose Irish moss worked better for me than protofloc tablets. It was a noticeable improvement in clarity.

* people say that quick chilling is key to a good cold break and therefore clearer wort. I've never not done this, so have no empirical evidence. I just do it as I need my wort at a temperature suitable for pitching the yeast.

* whirlpool after chilling and leave the wort to settle for 30-60 minutes. I find that the wort will naturally settle out during this time and I get very clear wort into the FV.

As for post-fermentation. Just be patient and it will clear. I've got a beer that had all kinds of fruit in the secondary and had no right to be clear. I just left it in my cellar (forgot about it in truth) for 3-4 months. Just bottled it last week and it's crystal clear. I always use Saf bottling yeast (1g per 25L is more than enough). It sets tight and you get clear beer from the bottle.

That's pretty much my key steps and it works for me.

I do treat my brewing liquor and have a good dose of DWB and calcium in the mash tun, plus AMS to soften the water a little. I've also started adding a 1/2 tsp calcium to the boil recently.

Re: Filtering beer

Lots of good points there, cheers, and welcome to the forum!

One thing I'm a bit confused about though now, I understood the idea of using irish moss/whirlfloc, and then cooling with an immersion chiller, and leaving for a while, as I can understand how the irish moss can then still work on precipitating the cold break.

If you use a plate chiller, how does the cold break form after chilling? As I'm assuming the irish moss isn't making it through the chiller.

One thing I'm a bit confused about though now, I understood the idea of using irish moss/whirlfloc, and then cooling with an immersion chiller, and leaving for a while, as I can understand how the irish moss can then still work on precipitating the cold break.

If you use a plate chiller, how does the cold break form after chilling? As I'm assuming the irish moss isn't making it through the chiller.

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: Filtering beer

What did he use liquid nitrogen?

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Re: Filtering beer

Yeah I'm confused by that, surely it's impossible to chill the whole batch in that time (unless we're talking very very small batches?)? Unless Eric just means chilling the output from the boiler using a plate/counterflow chiller to that temp, so 9 sec being the time for wort to enter and leave the plate chiller? But the full batch taking a lot longer than 9 sec?

- Eric

- Even further under the Table

- Posts: 2919

- Joined: Fri Mar 13, 2009 1:18 am

- Location: Sunderland.

Re: Filtering beer

It's a continuous process. Take a typical 10 to 100 barrel brewery where they will empty the kettle in well less than an hour. The beer is pumped through a cooler, maybe 1 to 5 metres high on the way to the FV. How long does the beer take to pass through the counterflow chiller while cold water passes from the bottom and comes out at about 75C at the top? It's just the same in homebrew, just smaller quantity flowing at the same speed, just a lesser volume and rate.chris2012 wrote: ↑Sat Aug 12, 2017 10:37 pmYeah I'm confused by that, surely it's impossible to chill the whole batch in that time (unless we're talking very very small batches?)? Unless Eric just means chilling the output from the boiler using a plate/counterflow chiller to that temp, so 9 sec being the time for wort to enter and leave the plate chiller? But the full batch taking a lot longer than 9 sec?

Just a few seconds.

Without patience, life becomes difficult and the sooner it's finished, the better.

Re: Filtering beer

Hi Eric

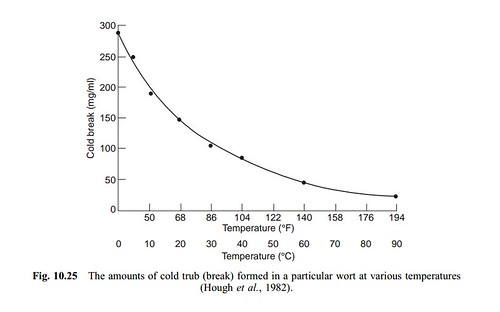

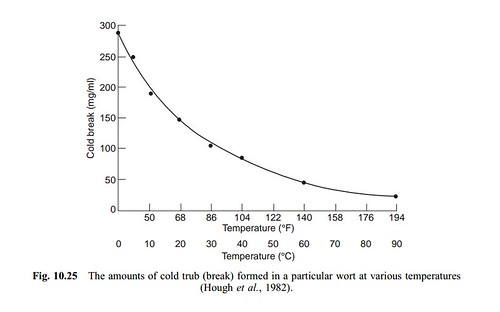

... because Hough, et al. found that the greater influence on cold break production was the temperature that the wort was cooled to ... as reported by Briggs in Brewing Science and Practice, Woodhead Publishing Limited, 2004 ...

... because Hough, et al. found that the greater influence on cold break production was the temperature that the wort was cooled to ... as reported by Briggs in Brewing Science and Practice, Woodhead Publishing Limited, 2004 ...

... so, you can use your immersion or counter flow chiller to chill your wort to (only) pitching temp of 20C or so, as fast you can, if you want ... but dropping your wort into a no-chill cube and allowing it to cool for 24 hrs at ambient temps, then putting your cube into your brewfridge to chill below 5C for a few days (or leaving it in the shed at ambient temperature, if ambient is cold enough), before transferring the wort to your FV, raising it to pitching temps and pitching CAN produce a "better" wort

... so, you can use your immersion or counter flow chiller to chill your wort to (only) pitching temp of 20C or so, as fast you can, if you want ... but dropping your wort into a no-chill cube and allowing it to cool for 24 hrs at ambient temps, then putting your cube into your brewfridge to chill below 5C for a few days (or leaving it in the shed at ambient temperature, if ambient is cold enough), before transferring the wort to your FV, raising it to pitching temps and pitching CAN produce a "better" wort

Cheers, PhilB

... but dropping the temperature of your wort from 80C to pitching temp isn't the whole picture, is itEric wrote: ↑Sat Aug 12, 2017 1:29 pmTestings took place in labs of brewers more than a hundred years since to determine optimum chilling rates. The findings depended upon beer style but basically between 7 and 9 second to drop wort from 80C to pitching temperature gave most benefits, not just based on clarity, leading to the introduction and widespread use of counterflow chillers.

Cheers, PhilB

-

sbond10

- Even further under the Table

- Posts: 2999

- Joined: Wed May 09, 2012 6:42 pm

- Location: Warrington England usually drunk or being mithered by my 2yr old or wife

Re: Filtering beer

Now that does throw a spanner in the work s but does link with what in said about it being crystal for a few litres.

Tho I've recently left a brew in the cube for about ten days whilst I wait for a fv so I may have to test your theory but this was at ambient temps

Tho I've recently left a brew in the cube for about ten days whilst I wait for a fv so I may have to test your theory but this was at ambient temps

Re: Filtering beer

This has turned into quite an interesting debate!

I suppose the bottom line for commercial breweries (and probably most of us as well) is not just what's technically the 'best way' but also what's practical and economic. A commercial outfit certainly couldn't afford to wait for a huge batch to cool naturally before pitching.

I find using a counterflow so straightforward and easy (and quick) that I wouldn't consider doing it any other way. I once boiled up 5 gallons of water to make up a wine kit, because I was being a bit anal about sterility, and let it cool naturally. I thought it would only take an hour or two to cool to pitching temperature so I could mix the kit and set it away. It took literally all day!

I suppose the bottom line for commercial breweries (and probably most of us as well) is not just what's technically the 'best way' but also what's practical and economic. A commercial outfit certainly couldn't afford to wait for a huge batch to cool naturally before pitching.

I find using a counterflow so straightforward and easy (and quick) that I wouldn't consider doing it any other way. I once boiled up 5 gallons of water to make up a wine kit, because I was being a bit anal about sterility, and let it cool naturally. I thought it would only take an hour or two to cool to pitching temperature so I could mix the kit and set it away. It took literally all day!

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: Filtering beer

I brew in a cellar, you can't get a better environment for all the things I don't want in my beer to abide. I have to get the wort pitched with a lot of yeast as soon as is practicable and right now the imperative is at its greatest. Once my FV is clean and sanitised it doesn't get exposed to the atmosphere again, pure O2 is used for aeration. A fast method of chilling in my circumstances is essential, if only because of the contamination risks, the other benefits are a bonus.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: Filtering beer

Don't think you have had an answer to this. Carrageenan has a negative electrostatic charge. Protein clumps from the boiling wort's hot break are positively charged. What it does is accelerates the clumping of proteins during the boil. If you have a sight glass on your boiler you can see this happening, it will begin to look like one of those Christmas globes that you shake to give the illusion of it snowing. It doesn't matter what you use to chill, the action of chilling of its self makes the "break" form into large clumps leaving the wort clear. So, it's the introduction of that negative charge that makes the initial difference which chilling, of any kind, accelerates.chris2012 wrote: ↑Sat Aug 12, 2017 9:44 pmOne thing I'm a bit confused about though now, I understood the idea of using irish moss/whirlfloc, and then cooling with an immersion chiller, and leaving for a while, as I can understand how the irish moss can then still work on precipitating the cold break.

If you use a plate chiller, how does the cold break form after chilling? As I'm assuming the irish moss isn't making it through the chiller.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Re: Filtering beer

Just to add to Orlando's reply, with a plate (or DIY copper pipe/hose) chiller, the cold break material ends up in the fermenter. However, this does not seem to have any negative effect on the beer.

Re: Filtering beer

Orlando - cheers, that makes sense now.

Jim - I didn't realise the cold break would end up in fermenter with a plate chiller, that's very interesting.

PhilB - That graph is very interesting. If I'm understanding correctly, the highest amount of cold break is formed at < 10C. So I could use a plate chiller to cool close to 0C, then warm up after a while?

Jim - I didn't realise the cold break would end up in fermenter with a plate chiller, that's very interesting.

PhilB - That graph is very interesting. If I'm understanding correctly, the highest amount of cold break is formed at < 10C. So I could use a plate chiller to cool close to 0C, then warm up after a while?

Re: Filtering beer

Remember that with any kind of counterflow chiller, you can't get any lower than the temperature of the cooling water.chris2012 wrote: ↑Sun Aug 13, 2017 9:30 amOrlando - cheers, that makes sense now.

Jim - I didn't realise the cold break would end up in fermenter with a plate chiller, that's very interesting.

PhilB - That graph is very interesting. If I'm understanding correctly, the highest amount of cold break is formed at < 10C. So I could use a plate chiller to cool close to 0C, then warm up after a while?

Re: Filtering beer

Oh yeah doh, so probably have to use a fridge/freezer.

I'll definitely try that next time I brew.

I guess I could use a temporary vessel, which has a filter on the outlet, so after the cold break has formed, I transfer to another vessel, that hopefully leaves the cold break behind.

or actually like someone mentioned before just siphon the wort of this vessel, leaving X amount behind.

Just as an aside, I've learned an absolute tonne from this thread! Thanks a lot everyone!

I'll definitely try that next time I brew.

I guess I could use a temporary vessel, which has a filter on the outlet, so after the cold break has formed, I transfer to another vessel, that hopefully leaves the cold break behind.

or actually like someone mentioned before just siphon the wort of this vessel, leaving X amount behind.

Just as an aside, I've learned an absolute tonne from this thread! Thanks a lot everyone!

- orlando

- So far gone I'm on the way back again!

- Posts: 7201

- Joined: Thu Nov 17, 2011 3:22 pm

- Location: North Norfolk: Nearest breweries All Day Brewery, Salle. Panther, Reepham. Yetman's, Holt

Re: Filtering beer

chris2012 wrote: ↑Sun Aug 13, 2017 10:06 amI guess I could use a temporary vessel, which has a filter on the outlet, so after the cold break has formed, I transfer to another vessel, that hopefully leaves the cold break behind.

or actually like someone mentioned before just siphon the wort of this vessel, leaving X amount behind.

The latter, if you mean direct from boiler to FV with no inbetween. Don't get too hung up about it there is no definitive answer to the question of cold break in or out of the FV. I would be much more concerned about minimising the ways cooled wort can pick up an infection before it enters the FV. That is definitely going to ruin your day, whereas the problem you are trying to avoid er, isn't.

I am "The Little Red Brooster"

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer

Fermenting:

Conditioning:

Drinking: Southwold Again,

Up Next: John Barleycorn (Barley Wine)

Planning: Winter drinking Beer